Introduction:

Elevate your electronic products with our Conductive Rubber Keypads, an essential component that guarantees a reliable connection and low resistance. Crafted from robust conductive silicone rubber, these keypads are meticulously designed for enduring use, ensuring long-term reliability. Thanks to their superior material quality and craftsmanship, they offer unparalleled durability and boast a quick turnaround for customized orders. What sets these keypads apart is their versatility; they can be tailored in various colors and shapes, catering to a myriad of applications. Whether you require sleek designs or vibrant hues, our Conductive Rubber Keypads provide the ideal solution. With their superior connectivity and lasting performance, you can trust these keypads to deliver a seamless experience in your electronic devices. Choose reliability, choose longevity – choose Conductive Rubber Keypads for unparalleled quality and functionality that ensures universal compatibility.

Specification:

Conductive Way: carbon pills, conductive ink printing, metal domes, metal pills

Surface Protective: PU coating, matte smooth coating, epoxy coating

Performance: aging resistance, cold resistance, heat resistance, chemical stability, waterproof, eco-friendly, durable

Certificate: ISO9001-2015, IATF16949, ROHS

OEM: available

Samples: free available samples

Packing: PE bag & carton, customized packing

Logo: silk printing, laser etching

Application: industrial, medical, automotive, consumer electronics, household, etc

Material: silicone rubber

Color: transparent or any colors

Hardness: shore A 30°~80°

Size: customized size

Tolerance: based on customer’s requirement

Printing: silk screen, radium carving

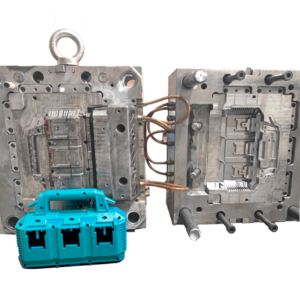

Molded Way: compression molded

Manufacturing Process:

- Material Preparation:Begin by preparing high-clarity elastomeric silicone rubber material, ensuring quality and consistency.

- Initial Vulcanization:Carry out the first vulcanization process using compression molding to create the base of the silicone rubber button pad, establishing its foundational structure.

- Color Application:Apply black and white color coatings meticulously to achieve the desired visual appearance, ensuring vibrant and uniform colors.

- Laser Etching:Utilize advanced laser technology to etch characters onto the surface of the buttons with precision and clarity, enhancing readability and aesthetics.

- Silkscreen Printing:Employ silkscreen printing techniques for detailed and intricate designs, enhancing the visual appeal of the buttons with sharp and clear patterns.

- Polyurethane Coating:Apply a PU polyurethane coating to the surface, imparting durability, resistance, and a smooth finish for a comfortable touch and extended lifespan.

- Epoxy Coating:Implement epoxy coating on the keys to enhance their resilience and longevity under various conditions, ensuring they withstand wear and tear.

- Burr Removal:Conduct a precise die-cut process to remove any burrs or imperfections from the silicone button membrane, ensuring a seamless and polished final product. This meticulous step guarantees a flawless surface and optimal functionality of the buttons.