What Is Silicone Rubber Compression Molding?

Silicone rubber compression molding is a manufacturing process that shapes silicone rubber products through the application of heat and pressure. This technique is utilized for the production of a wide range of silicone rubber items, including seals, isolators, gaskets, handles, buttons, and various rubber components. Silicone rubber compression molding is frequently chosen for crafting components with precise dimensions and shapes, especially for items demanding exceptional heat resistance, chemical resistance, and excellent elasticity. This process results in products characterized by outstanding surface quality and dimensional stability, making it a popular choice across various industries.

Two-plate mold: It is the most simple and traditional compression mold, which is suitable for simple structure parts without undercuts, such as silicone seals, silicone o-ring, silicone keypad.

Three-plate mold - upper and lower mold+middle plate: this kind of mold is a good choice for the parts with undercuts. Such as silicone grommet, silicone umbrella valve. For silicone grommet, choose this structure mold, the grommet will have good appearance without large parting line on the surface. But middle plate is not easy to demold, so it's not suitable for high hardness grommet. If the hardness is over 60A, we will suggest to make upper and lower mold with moving core.

Three-plate mold - upper and lower mold + core (moving core): which is mainly for silicone sleeve, and complicated structure parts.

Our compression molding service

Precision Silicone Rubber Compression Molding Solution

We take pride in delivering top-notch mould for silicone production with a focus on quality and on-time delivery. Our advanced infrastructure is equipped to handle your unique and intricate design requirements efficiently. Utilizing "Rubber Compression Molding" technology, we specialize in producing silicon products in low to medium-order quantities. Our team of experienced professionals will provide expert guidance and support, ensuring you find the perfect solution for your business needs.

Material Expertise: We have extensive knowledge and experience in working with various silicone rubber materials, allowing us to recommend the most suitable material for your specific application. Whether you require high-temperature resistance, excellent electrical insulation, or biocompatibility, we have the expertise to meet your requirements.

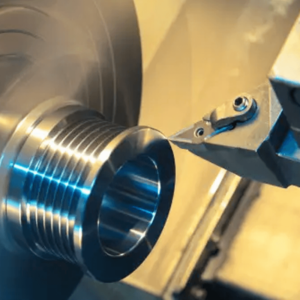

Advanced Tooling and Mold Design: Our solution incorporates cutting-edge technology and expertise in tooling and mold design of rubber compression. We leverage CAD/CAM software and precision machining to create high-quality molds that ensure accurate replication of your desired product.

Design Flexibility: With our Precision silicone compression mould Solution, you have the freedom to design and create complex shapes, intricate details, and precise dimensions. We work closely with you to transform your ideas into reality, ensuring that your product meets your exact specifications.

Surface Finish and Aesthetics: Our Precision Silicone Rubber Compression Molding Solution enables the production of parts with superior surface finish and aesthetics. We pay meticulous attention to detail, ensuring that your products not only perform flawlessly but also have an appealing appearance.

In-house capabilities

Not being dependent on outside sources allows us to maintain complete control of every job, ensuring quality products, shorter lead times, on-time delivery, and competitive prices for our customers.

Certificate And Silicone Report:

ISO 9001:2015, IATF16949, FDA, ACS, KTW, W270

Applications of Silicone Rubber Compression Molding

- Automotive Industry: Gaskets, O-rings, Weatherstrips, etc.

- Automotive components: Engine gaskets, Sound dampening pads, etc.

- Exterior vehicle parts: Headlight seals, Window gaskets, etc.

Medical Industry: such as surgical instruments, medical tubing, catheters, nipples, etc.

Medical aids: such as artificial prosthetics, breast implants, eye masks, breathe mask, etc.

Electronics Industry: such as cable connectors, electronic device gaskets, etc.

Insulation materials: including high-temperature insulation pads, gaskets, etc.

Household Appliances and Kitchenware: Kitchen utensils: like baking mats, baking molds, etc.

Industrial Equipment Industry: Used for sealing rings, protective sleeves, vibration isolators, pipe fittings, and rubber pads.

Appliances Industry: Used for electrical insulation components, seals, hoses, shock-absorbing pads, and buttons.

Consumer Goods Industry: Used for toys, kitchenware, shoe insoles, handles, and household items.

Aerospace Industry: Used for aerospace seals, vibration dampers, rubber hoses, and rubber pads.

Construction Industry: Used for construction seals, slope protection components, retaining boards, and soundproofing pads.

Quality and Precision

We are dedicated to delivering the utmost quality and precision in silicone compression molding services. Our advanced process harnesses the exceptional properties of silicone materials, ensuring the creation of parts with unparalleled flexibility and durability. Whether you require a single prototype or long-term production parts, our expertise can help you achieve the exact components you need with excellence.

Benefits of Silicone Compression Molding

Design Flexibility: Silicone rubber compression molding allows for the production of complex shapes, intricate details, and precise dimensions. It offers design versatility, enabling the creation of customized and unique products to meet specific requirements.

Material Versatility: Silicone rubber is available in a wide range of formulations, allowing for the selection of materials with different hardness, colors, and properties. This versatility makes silicone rubber suitable for diverse applications across industries.

High-Quality Surface Finish: Compression molding ensures excellent surface quality with minimal defects, providing a smooth and consistent finish. This makes it ideal for applications where aesthetics and surface appearance are crucial.

Consistency and Precision: The compression molding process enables consistent production of parts with uniform dimensions, shape, and material distribution. This results in reliable and repeatable product quality, meeting strict specifications and tolerances.

Enhanced Mechanical Properties: Silicone rubber exhibits excellent mechanical properties, including elasticity, flexibility, and resilience. Compression molding allows for the creation of durable and resilient parts that can withstand a wide range of operating conditions.

Chemical and Heat Resistance: Silicone rubber has excellent resistance to chemicals, heat, and aging. It can maintain its properties over a wide temperature range, making it suitable for applications requiring resistance to harsh environments.

Cost-Effective Production: Compression molding is a cost-effective manufacturing method, particularly for medium to large production volumes. It allows for efficient material utilization and short cycle times, reducing production costs.

Sustainability: Silicone rubber is a recyclable material, and compression molding produces minimal waste. The process aligns with sustainable manufacturing practices, contributing to environmental conservation.

Compression Molding Process

- 1.Raw Material Preparation: Ensuring silicone rubber meets requirements.

- 2.Mold Preparation: Key to successful molding.

- 3.Filling and Curing: Filling the mold and initiating curing.

- 4.Cooling and Solidification: Ensuring stable dimensions and shapes.

- 5.Demolding & Post-Processing: Smooth product removal and further processing.

- 6.Inspection and Packaging: Guaranteeing quality before shipping.

Silicone Compression Molding VS Liquid Injection Molding

Cost-effective: Compression molding is more affordable than liquid injection molding due to its simpler mold design and the ability to produce multiple cavities without costly tooling.

Quick Mold Making: Compression molding boasts shorter mold making times, typically taking around 15-20 days, and for simpler parts, just 7-10 days are sufficient. In contrast, liquid injection molding requires a longer period of 40-55 days for mold fabrication.

Simplified Maintenance: Compression molds have a straightforward structure, making them easier to maintain and set up compared to liquid silicone injection molds. Setting up a silicone compression mold typically takes only about 1 hour, while assembly for a liquid silicone injection mold can take around 1 day.Versatile Material Choices: Compression molding offers a wide range of material options, especially suitable for flexible materials that retain pliability after the curing process. Moreover, it accommodates thermosets, allowing the molding of multiple cavities. Commonly utilized materials include silicone, natural rubber, and EPDM.

Ample Production Capacity: Compression molding machines typically have high production capacity, allowing for efficient mass production. The ability to incorporate multiple cavities in a compression mold results in a higher output compared to injection molding methods.

Variety of Color Options: Compression molding allows for testing different colors more easily compared to liquid injection molding. The mold can be cleaned, and colored silicone can be milled and placed into the cavity for different color tests. However, liquid injection molding requires a longer time (usually about half a day) to clean the color system and needles, resulting in time and material wastage. As a result, liquid injection molding is generally not used for testing different colors.

Important attention when performing silicone rubber compression molding

Mold design and preparation: Ensure that the mold design meets the product requirements and has appropriate ventilation and cooling systems. Ensure that the mold surface is smooth, free from scratches, and undamaged.

Material selection and formulation: Choose the appropriate silicone rubber material, considering the desired physical properties, chemical resistance, and temperature resistance. Ensure accurate mixing of silicone rubber material and additives to achieve the desired hardness and performance.

Heating and pressure control: Strictly control the heating and pressure parameters to ensure that the silicone rubber material becomes fluid at the proper temperature and pressure, filling the mold cavity.

Curing time and temperature: Control the curing time and temperature based on the type and requirements of the silicone rubber material. Ensure sufficient curing to achieve the desired strength and shape.

Cooling and demolding: Ensure that the silicone rubber material is adequately cooled before demolding. Premature demolding may result in part deformation or damage.

Applications

Silicone rubber compression molding is widely used in various industries and fields, including:

- Automotive Industry: including gaskets, O-rings, weatherstrips, etc.

- Automotive components: such as engine gaskets, sound dampening pads, etc.

- Exterior vehicle parts: like headlight seals, window gaskets, etc.

- Medical Industry: such as surgical instruments, medical tubing, catheters, nipples, etc.

- Medical aids: such as artificial prosthetics, breast implants, eye masks, breathe mask, etc.

- Electronics Industry: such as cable connectors, electronic device gaskets, etc.

- Insulation materials: including high-temperature insulation pads, gaskets, etc.

- Household Appliances and Kitchenware: Kitchen utensils: like baking mats, baking molds, etc.

- Industrial Equipment Industry: Used for sealing rings, protective sleeves, vibration isolators, pipe fittings, and rubber pads.

- Appliances Industry: Used for electrical insulation components, seals, hoses, shock-absorbing pads, and buttons.

- Consumer Goods Industry: Used for toys, kitchenware, shoe insoles, handles, and household items.

- Aerospace Industry: Used for aerospace seals, vibration dampers, rubber hoses, and rubber pads.

- Construction Industry: Used for construction seals, slope protection components, retaining boards, and soundproofing pads.