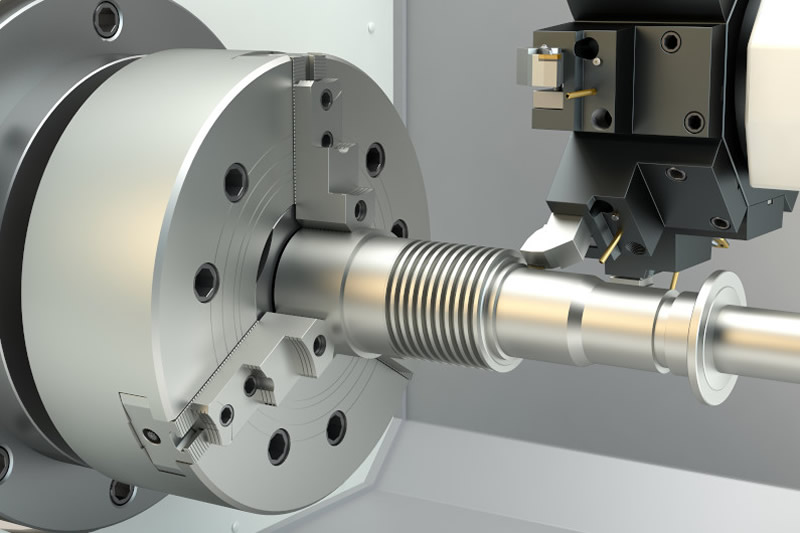

What Is CNC Turning

CNC Turning, also known as Computer Numerical Control Turning, is a manufacturing process that involves securing bars of material within a chuck and rotating them while a tool is progressively fed towards the material to remove excess material, thus shaping it into the desired form. A central turret, as depicted in the center, carries tooling attachments and is programmed to move towards the raw material bar, selectively removing material to achieve the programmed outcome. This process is often referred to as "subtraction machining" because it centers on material removal. In cases where the machining center possesses both turning and milling capabilities, like the one described above, the rotation can be halted to facilitate milling operations for creating different shapes.

Our CNC Turning Service

ThesunIndustry is a reliable company that takes pride in its team of expert CNC machinists and tool and die makers,even when dealing with the most complex parts. With our state-of-the-art facilities, we can produce close tolerance parts with a precision of +/- .001" or better, accommodating components as large as 10" in diameter.

Our CNC turning center, which includes a full C-axis and Y-axis, is equipped with an advanced automated tool pre-setter. The integration of this tool pre-setter allows for automatic tool wear detection, effectively minimizing downtime and maximizing production efficiency.

CNC Horizontal Turning

Lingshantech provides CNC horizontal turning service, offering the capacity to manufacture parts weighing up to 950 lbs., with dimensions of up to 44″ in length and 25″ in diameter. Additionally, we can produce small parts as slim as 1/8″ wide, adhering to precise tolerances. Our 3-axis, live tooling-equipped turning center allows us to perform various operations, such as internal and external threading, knurling, profiling, and more.

CNC Vertical Turning

Lingshantech offers comprehensive CNC vertical turning services catering to a diverse range of industries, including construction, farm equipment, aerospace, and defense. Our focus lies in producing precision machine components with tight tolerances and rapid turnaround times. We are capable of manufacturing parts with a maximum length of 21.5″, a maximum diameter of 51″, and a maximum weight of 20,000 lbs.Our capabilities encompass a wide array of machining techniques, including contour and straight turning, internal forming, counterboring, pocketing, and more.

Quality Control

When you choose ThesunIndustry, you can be confident in receiving superior CNC turning solutions backed by our unwavering commitment to quality, efficiency, and customer satisfaction.

Rapid Turnaround

We use the latest CNC turning machines and cutting tools to produce 1-precision, fast-turned parts within one day.

Wide Range of Materials

Choose from more than 100 kinds of metal and plastic materials, and provide corresponding quality assurance.

High Precision

Provide unparalleled precision and quality without cutting corners. High precision tolerances range from +/- 0.003mm, according to customer specifications.

Competitive Price

We have a stable supplier of raw materials and can quickly provide customers with competitive quotations.

Engineering Support

Whether the customer needs to machine 1 or 10,000 parts, we have a professional engineers team to provide technical support.

Available Materials for CNC Turning

| Aluminum Al6061 / Al6063 / Al6082 / Al7075 / Al5052 / A380, etc. |

Steel Mild Steel, Alloy Steel, etc. |

Plastic PET / PVC / ABS / PC / PE / PTFE / POM / PMMA / Nylon / PP / Peek, etc. |

| Cooper C11000 / C12000 / C12000 / C36000, etc. |

Stainless Steel Stainless-steel 303 / 304L / 316L / 416 / 440C |

Titanium TA0 / TA1 / TA2 / TC4 / TB5, etc. |

CNC Turning Tolerances

As an ISO 9001 certified company, we machine CNC turning lathe parts to meet tight tolerance requirements. Based on your design, our CNC lattes can reach tolerances of up to ±0.005”. Our standard tolerances for CNC milled metals is ISO 2768-m and ISO 2768-c for plastics.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

Surface Finishes for CNC Turning

We offers a diverse range of surface finishes to enhance the quality of your CNC turned parts. These finishes are applied with the objective of improving appearance, surface hardness, roughness, chemical and corrosion resistance, among other benefits. Additionally, they help conceal any visible tool marks resulting from areas cut with live tooling. Here are some of our top choices for surface finishes:

Grinding: Grinding using abrasive tools can achieve a very smooth surface, eliminating any traces and irregularities that may have been left during the cutting process.

Polishing: Polishing involves the use of polishing agents and tools to enhance the surface gloss and smoothness, making it more even and reflective.

Sandblasting: Sandblasting is the process of spraying fine particles onto the surface of the part to remove roughness and create a uniform matte effect.

Electropolishing: This method improves surface smoothness and uniformity by treating the part in an electrolyte solution.

Chemical Etching: Chemical etching involves using specific chemical liquids to etch the surface of the part, allowing for the processing of details, patterns, and improving surface quality.

Laser Marking: Laser marking uses a laser beam to engrave patterns, text, or markings on the part's surface, achieving high-precision marking and decorative effects.

Hardening: Hardening involves heat or chemical treatment of the part's surface to enhance hardness and wear resistance.

Coating: Coating involves applying a layer of special material, such as chrome plating, nickel plating, zinc plating, etc., to provide additional protection and improve the part's corrosion resistance.

Anodizing: An electrochemical treatment that forms a protective and corrosion-resistant oxide layer on the surface.

Our High Standards For CNC Turning

We prioritize the production of your custom parts in strict compliance with rigorous manufacturing standards, ensuring adherence to the strict standard. To ensure quality, we conduct thorough verification of these requirements and include an inspection report with each order we ship.

Following the completion of the turning process, the parts can be left in their turned state or undergo post-processing as specified in the customer's requirements outlined in the purchase order (PO). This post-processing aims to enhance surface properties and achieve a visually appealing cosmetic appearance.

Our in-house quality checks are conducted before the Manufacturing Partner (MP) sends the custom parts to our facilities or their final destinations. These checks guarantee that every part adheres to the specifications outlined in the order and meets the high standards set by Lingshantech. Any requested documentation is also completed at this stage, ensuring the conformity of the parts before they are shipped out.

ThesunIndustry upholds a 100% commitment to quality according to ISO9001 and IATF 16949 standards. We maintain strict quality control throughout every step of the production process, from incoming quality inspection of materials to outgoing quality inspection.

We take great pride in our dedication to rigorous quality control and providing exceptional customer service. Our goal is to exceed customer expectations in all aspects of the product manufacturing process, recognizing the significant responsibility we have towards our customers.