Tooling Manufacturing

We Provide High Quality Molded Parts Production Tooling Service

What is Tooling in Manufacturing?

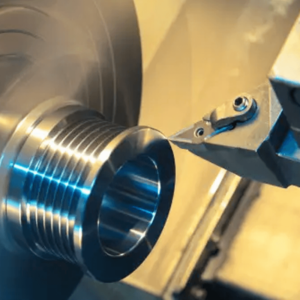

Tooling in manufacturing — also known as machine tooling or mold making — is the process of designing, cutting, shaping, and forming materials that will be used to produce tight-tolerance parts and components.

Our Powerful Tool & Mold Building Service:

Decades of tooling design expertise extend across various specialized areas, including Plastic Injection Molding, LSR injection molding, plastic and LSR over-molding, silicone compression molding, and silicone and plastic extrusion. We take pride in exceeding the most stringent customer specifications and adhere to ISO 9001 and IATF 16949 quality management standards, ensuring that our results not only meet but surpass customer expectations.

- Professional Engineering

Our expert Mold Design Team offers practical and cost-effective solutions to minimize customer development and tool-making expenses. - Precise Manufacture

With world-class processing machines and testing equipment, we excel in manufacturing precise and complex molds, achieving 5-micron precision. - Quality Control

Equiping with precision processing and production equipment, and strictly adhere to the quality control processes of ISO9001 and ISO16949 to ensure quality control. - Project Management

Our Bilingual Project Engineers with many experiences ensure smooth project operations and communication.

Advantages of Our Tooling Manufacturing Service

Advanced Equipment and Technology

Our inventory includes cutting-edge manufacturing machinery and technology, encompassing high-precision CNC machines, state-of-the-art CAD/CAM software, and advanced 3D printing capabilities. These sophisticated tools empower us to attain precision in tooling production, allowing us to execute intricate details and intricate shapes with unparalleled accuracy.

Tailored Design and Engineering Assistance

Our collaborative approach involves close engagement with our clients, allowing us to acquire a profound comprehension of their unique needs and precise product specifications. Our seasoned team of engineers offers expert design counsel and engineering support, guaranteeing that the tooling design not only aligns with customer expectations but also meets the exacting demands of the product.

Superior Materials and Stringent Manufacturing Standards

Our rigorous material selection process focuses on the meticulous choice of high-caliber materials, including premium-grade steel and wear-resistant alloys, for our tooling. Furthermore, we unwaveringly adhere to exacting quality control standards and procedures to guarantee the consistent quality of every piece of tooling manufactured. This steadfast commitment translates into heightened durability, stability, and longevity of the tooling.

Technological Advancement and Ongoing Enhancement

As a factory propelled by innovation and dedicated to continuous improvement, we perpetually strive for technological advancement, delving into novel manufacturing techniques and materials. By integrating cutting-edge processes and technologies, we elevate the precision, intricacy, and production efficiency of our tooling, aligning with the dynamic requirements of the evolving market.

| Machinery | Quantity |

| High speed of 42000 and precision CNC | 2 |

| Other 7 CNC Machines | 7 |

| Makino Sinker EDM | 4 |

| Sodic Wire EDM | 5 |

| High Precision Grinder | 5 |

Tooling for Plastic and LSR Injection Molding

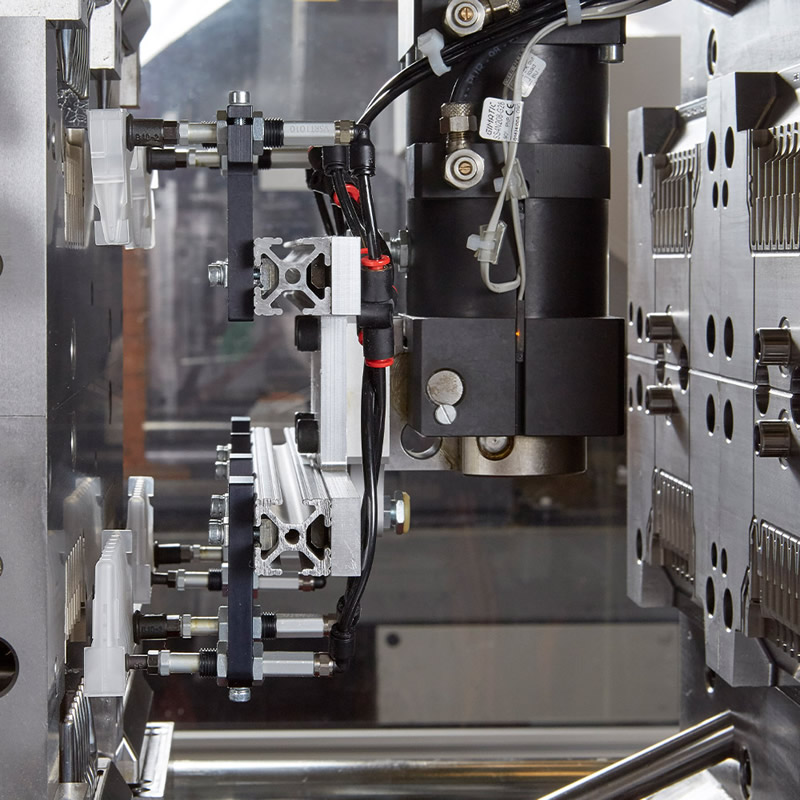

Designing tooling for complex plastic and Liquid Silicone Rubber (LSR) parts in injection molding is a highly technical and intricate process that demands precision and expertise. We prioritize mold design as the core, providing exceptional solutions for the injection molding of intricate plastic and LSR components.

For plastic parts, we employ a meticulous approach to select the appropriate materials. Through advanced simulation software for flow analysis, we optimize the mold design to ensure reduced defects during the plastic filling process. Simultaneously, we excel in mold cooling techniques, effectively regulating the cooling process to enhance production efficiency while maintaining part quality.

In the realm of Liquid Silicone Rubber injection, we confront unique challenges. Our mold design controls the curing process to ensure precise part dimensions and performance. We carefully select materials compatible with LSR to prevent adverse reactions and ensure mold integrity and part quality.

Our commitment to continuous improvement keeps us at the forefront of injection molding technology, delivering innovative solutions that optimize production efficiency and elevate product quality.

In-House Design and Tool Adjustments

Injection molders often rely on external tooling builders to custom-build the initial tooling. However, it's common for molds to require adjustments after qualification to ensure they meet all design specifications. We take a different approach to handle most of these adjustments in-house, allowing us to "fine tune" the tools after initial sampling. This enables us to improve the tool core/cavity geometry and achieve precise dimensions without lengthy delays.

Tooling for Over-molding

Precision Mold Design:Our experienced engineering team utilizes advanced CAD/CAM software for precise mold design, tailored specifically for over-molding applications. By optimizing runner systems and cooling channels, we ensure uniform material flow and efficient cooling, resulting in superior over-molded part quality.

High-Quality Mold Materials: Over-molding places unique demands on molds, and to meet these challenges, we carefully select high-quality mold materials like hardened steel or specialized alloys. These materials offer exceptional wear resistance, extending mold lifespan and enhancing production efficiency.

Advanced Manufacturing Technology: Equipped with state-of-the-art CNC machines and EDM equipment, we achieve the highest level of precision and complexity in over-molding molds. This accuracy translates into over-molded parts with strict tolerances and consistent dimensions, meeting the exacting requirements of the process.

Customization and Flexibility: Over-molding projects can vary significantly, and our mold solutions are customized to cater to specific design and material needs. Our team collaborates closely with yours, ensuring seamless integration and optimal results.

By harnessing these advantages, our over-molding molds deliver outstanding performance, providing high-quality over-molded parts for your unique applications.

Mould Making Process

- 1.Product3D checking and DFM

- 2.Tooling design and get approval

- 3.Mold material purchase

- 4.Bold building of CNC and EDM process,

- 5.Auxiliary machining such as wire EDM, drilling and grinding

- 6.Polishing

- 7.Mold assembly

- 8.Quality Control

- 9.T0 and P0 sample for customer approval

- 10. Packing and delivery

Applications of the Mold’s Production We Served

The molds produced by ThesunIndustry have diverse application fields, showcasing their versatility and precision. Some of the key areas where these molds find extensive use include:

Electronics Industry: Our molds are essential in manufacturing plastic and silicone components for electronic devices. They play a crucial role in producing phone casings, computer accessories, and other electronic components with high precision and reliability.

Kitchen & Bath: In the household sector, Lingshan's molds are widely used for creating various kitchen utensils, home appliances, and bathroom accessories. These molds ensure the production of high-quality, functional, and aesthetically appealing products.

Automotive Sector: Our molds are employed to manufacture automotive components, such as car interior parts, exterior trim, and lighting components. These molds maintain the necessary precision and durability required for the automotive industry's stringent standards.

Medical Components: The molds produced by Lingshan Technology are also applied in the medical equipment industry. They are used to create medical device components, ensuring the safety and reliability of critical medical equipment.

Industrial Equipment: Our molds are utilized to fabricate various plastic and silicone components for industrial machinery. These molds contribute to the durability and efficiency of industrial equipment.

The expertise and innovation of ThesunIndustry in mold manufacturing enable them to cater to diverse industries with tailor-made solutions. With a focus on precision and quality, their molds enhance the production processes and performance of products in various sectors.