Overview:

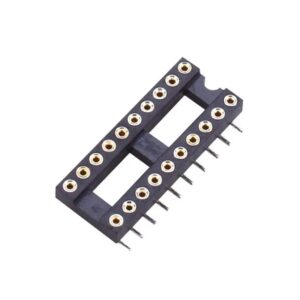

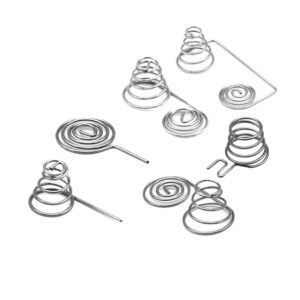

Precision Engineered Stainless Steel Fitting: Expertly machined from top-tier 630 stainless steel, this CNC-turned and milled component exemplifies unmatched precision. Available in lengths from 12mm to 16mm, it harmonizes intricate front-end details with consistent rear-end dimensions. Stringent machine checks after each production batch ensure impeccable parameter accuracy. The front end boasts an independent thread and pin design, meticulously crafted using a milling-before-turning technique, guaranteeing exceptional durability. The middle section features a threaded structure with a nut, allowing effortless bolt push distance adjustments. The back end, reminiscent of a bolt handle, offers streamlined simplicity and superior functionality. Laser-engraved product numbers enhance traceability and quality assurance. Despite its intricate design, our prototype garnered outstanding feedback, setting the stage for upcoming mass production.

Specification:

Material: brass, phosphor copper, beryllium copper, stainless steel SUS304/301, etc.

Color: gold, silver, black or as per customers’ requirement

Surface treatment: tin plating, nickel plating, silver plating, gold plating, etc.

Tolerance: 0.02mm-0.1mm

Production equipment: independent research and development design and mold making; high-speed precision continuous punching machine and high-speed electric injection molding machine

Oxidation test: salt spray test

Certificate: ISO9001

Free samples: available

Sample Time: 7-12 Days

Lead Time: 15-25 Days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Packages Term: plastic bag + Carton + Pallet

Delivery Term: by sea/express

Application: automotive and railroad components, medical equipment, marine machinery, lighting fixtures, pump bodies, valve components, architectural elements, and furniture manufacturing.

Application:

- Automotive and Railway Systems: Essential for critical components in automobiles and railway systems, ensuring precision and longevity in engine parts, suspension systems, and safety devices.

- Medical Devices: Vital for medical equipment, these components are utilized in surgical instruments, implants, and diagnostic devices, guaranteeing accuracy and reliability in healthcare settings.

- Marine Engineering: Crucial for marine applications, these components contribute to the construction of robust and corrosion-resistant marine engines, propellers, and essential ship machinery.

- Lighting Solutions: Utilized in high-quality lighting fixtures, ensuring stability and durability in various commercial and residential lighting solutions.

- Industrial Fluid Systems: Integral in pump bodies and valve components, ensuring efficient fluid flow and precise control in industrial processes, water management, and HVAC systems.

- Architectural Structures: Employed in architectural projects, enhancing aesthetically pleasing and structurally sound elements like railings, decorative panels, and fittings.

- Furniture Production: Incorporated into furniture manufacturing, ensuring the creation of durable and visually appealing furniture pieces, including fittings and joints.