Description:

Step into TheSun Industry, where innovation meets perfection! We’re thrilled to showcase our best-selling Water Faucet Valves – a pinnacle of precision and endurance. These valves redefine the essence of water delivery, offering not just a function but an experience.

Immerse yourself in the seamless fusion of advanced technology and elegant design. Our Water Faucet Valves guarantee leak-proof performance and effortless operation, setting a new standard for reliability. But that’s just the beginning!At Thesun Industry, we prioritize your satisfaction. Experience prompt deliveries, responsive customer support, and a commitment to quality that goes beyond industry norms. Our valves have transformed spaces for satisfied customers, offering a blend of functionality and aesthetics.Choose Thesun Industry, and elevate your faucet experience to new heights. Indulge in quality, embrace innovation, and welcome a new era of water flow. Discover the difference with our Water Faucet Valves today!

Basic Information:

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Industrial |

| After-sales Service | Available |

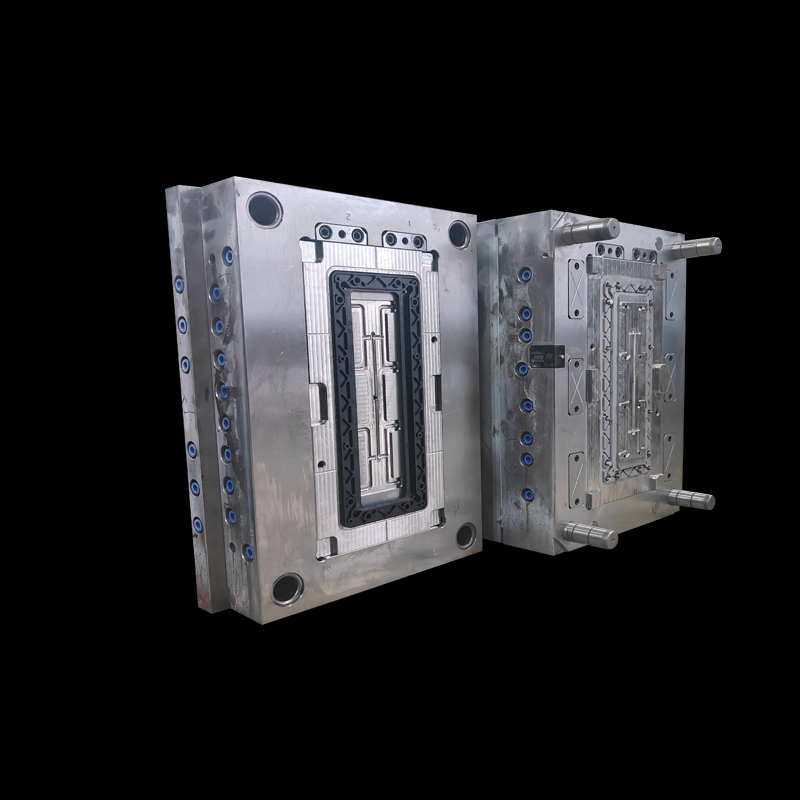

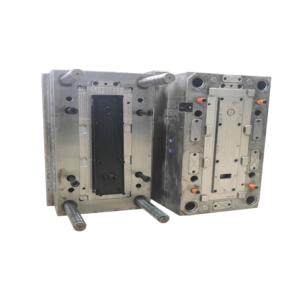

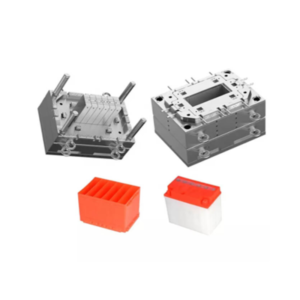

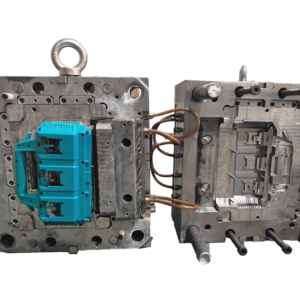

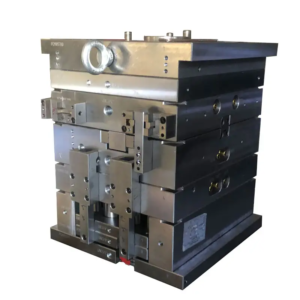

| Mould Type | Plastic Injection Mold |

| Production Process | Injection Molding |

| OEM&ODM | Available |

| Mould Lead Time | 4~7 Weeks |

| Design | 3D or 2D |

| Transport Package | Wooden Box |

| Sample | Available |

| Color | Custom |

| Specification | customized |

| Production Capacity | 500sets/Year |

| Origin | Xiamen,China |

| Molding surface treatment | Polishing |

| Mould Life | 100 thousand~300 thousand times |

| Quality System | ISO9001,SGS,TS16949 |

| Fast mold design | We can be within 1-3 working days after getting customer’s drawings. |

Surface Treatment:

Plastic injection molds for water faucet valves may undergo various surface treatments to enhance their performance, durability, and appearance. The choice of surface treatment depends on the specific requirements of the application and the type of plastic used. Here are some common surface treatments for plastic injection molds:

-

Polishing:

– Purpose:Improves the mold’s surface finish and appearance.

– Method:Mechanical polishing or chemical polishing processes.

-

Texture or Grain Finish:

– Purpose: Adds a specific texture or pattern to the molded part’s surface.

– Method:Applied to the mold surface to transfer the texture to the plastic during molding.

-

Nitriding:

– Purpose:Increases surface hardness and wear resistance.

– Method:Introducing nitrogen into the mold surface, forming a hard nitride layer.

-

Chrome Plating:

– Purpose:Enhances corrosion resistance and reduces friction.

– Method:Electroplating a thin layer of chromium onto the mold surface.

-

Teflon Coating:

– Purpose:Reduces friction, improves release properties, and minimizes material buildup.

– Method:Applying a thin layer of Teflon or similar non-stick coatings.

-

EDM (Electrical Discharge Machining) Finish:

– Purpose:Achieves a smooth and precise surface finish.

– Method:Uses electrical discharges to remove material and create a fine surface.

-

Hard Chrome Plating:

– Purpose:Provides a harder and more wear-resistant surface.

– Method:Similar to chrome plating but with a thicker layer for increased durability.

-

Powder Coating:

– Purpose:Adds color and improves the appearance of the mold.

– Method:Electrostatically applying dry powder to the mold surface and curing it with heat.