Introduction:

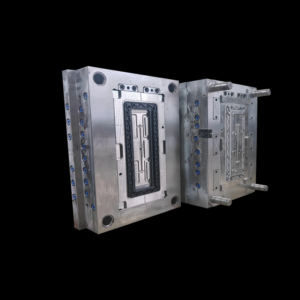

The Bathroom Faucet Switches Mold, crafted using precision injection molding technology, produces high-quality faucet switches for bathroom fixtures. This intricately designed mold not only ensures durable and precisely engineered components but also allows for the creation of water-saving switches, providing maximum assistance in your water conservation efforts. The production process emphasizes efficiency, precision, and consistency, making it an ideal choice for manufacturing top-notch and environmentally friendly bathroom faucet switches.

The Production Process Of The Bathroom Faucet Switches Mold:

- Design Phase:Initially, designers create the mold design based on product requirements and specifications. This may include using Computer-Aided Design (CAD) software to draw a three-dimensional model, considering factors such as materials, dimensions, structure, and functionality.

- Mold Manufacturing:Once the design is complete, manufacturers produce the mold according to the design. Typically, this involves cutting or machining metal (usually steel or aluminum alloy) into the shape of the mold. This process may also involve techniques such as electrical discharge machining (EDM), milling, drilling, etc.

- Injection Molding:The manufactured mold is then mounted onto an injection molding machine. During the injection molding process, heated plastic pellets are injected into the mold, filling the mold cavity. The plastic then cools and solidifies, taking the shape of the desired product.

- Cooling and Mold Opening:Once the plastic has cooled and solidified, the mold is opened, allowing for the removal of the molded product. The control of cooling time and the speed of mold opening/closing impact the final product’s quality.

- Post-Processing:The molded product may undergo post-processing steps such as removing excess material, polishing, surface treatments, etc., to ensure the product meets the desired quality standards.

- Inspection and Quality Control:The finished product typically undergoes inspection to check dimensions, appearance, and functionality, ensuring it meets the required specifications. Quality control measures help ensure that each product meets standards.

- Delivery and Utilization:The completed mold-produced products are delivered to customers or assembled into the final product. These products will be used for the switch functionality in bathroom faucets.

Our Service:

- Prompt Responsiveness:We prioritize swift responses to your inquiries, ensuring timely communication.

- Custom Solutions:Our expertise lies in providing customized solutions, tailored to your specific needs and preferences.

- Professional Consultation:Benefit from our professional insights and guidance to make informed decisions for your projects.

- Quality Assurance:We are committed to delivering high-quality products and services to meet and exceed your expectations.

- Versatility:Whether you require specialized manufacturing, innovative designs, or comprehensive project management, our services are versatile to accommodate diverse needs.