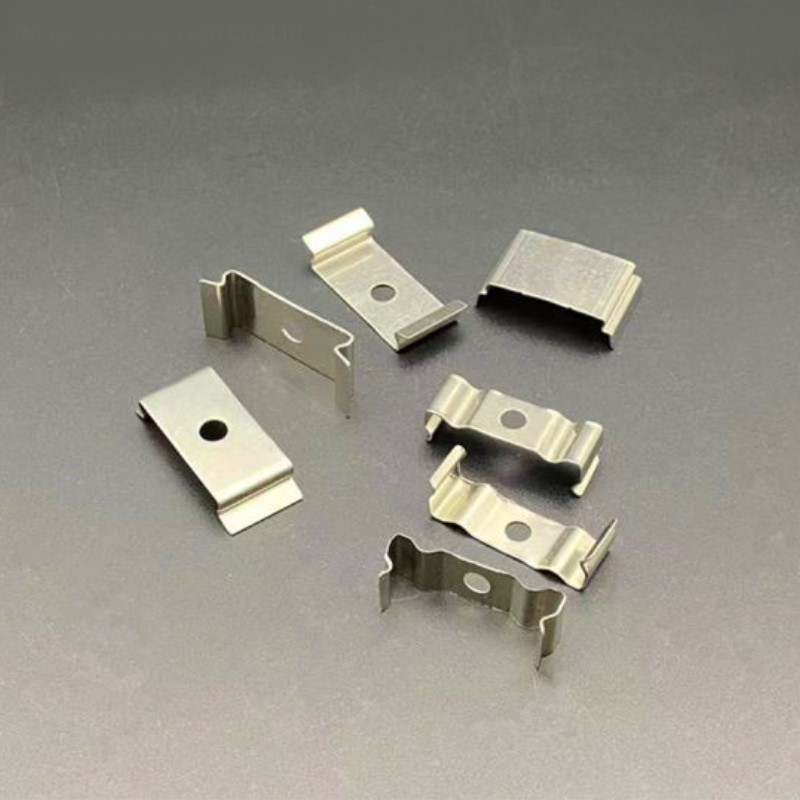

Overview:

Introducing our Custom Spring Steel Clips Stamping Clips for LED Strip Light—versatile and precision-engineered. Crafted from steel, stainless steel, brass, and more, these clips offer tailored sizes and colors for a perfect fit in any application. With a remarkable 0.01mm tolerance, they undergo rigorous testing, ensuring durability through 48H salt-spray, 2D, and plainness tests. ISO 9001 certified, each clip is subject to 100% inspection before shipment. Ideal for machinery, electronics, furniture, and automotive applications, these clips provide secure fastening for LED strip lights. Our OEM/ODM options allow customization to meet specific needs. Enjoy free samples with a quick 7-12 day lead time and a 15-25 day lead time for production. Flexible payment terms include T/T and L/C. Illuminate your projects with precision—choose Custom Spring Steel Clips for reliable and customized LED solutions.

Specification

Materials: steel, stainless steel, brass, copper, bronze, aluminum, titanium, etc

Size: as customers’ request

Color: according to customers’ needs

Tolerance: 0.01mm

Process: CNC machining(turning, milling, drilling)

Surface treatment: polishing, sandblasting, anodizing, brushing, powder coating, electroplating, zinc plating, silk-screen

Test: 48H salt-spray testing, 2D testing, plainness testing

Quality Control: 100% inspection before shipment

Certifications: ISO 9001

OEM: available

Samples: free available

Sample Time: 7-12 Days

Lead Time: 15-25 Days

Payment Term: T/T, L/C 30% deposits, before the ship to pay the balance end. Freight are quote under your request

Packing: plastic bag, carton or wood case and pallet or according to customer’s needs

Delivery Term: by sea/express

Application: machinery, chemical industry, environmental, furniture, industrial, construction, electronic, appliance, automotive

Surface Finishing Options

- Brush Finish: Achieving a consistent brushed texture, enhancing both visual appeal and tactile experience.

- Mirror Polishing: Employing precise techniques for a sleek, reflective surface, ensuring a sophisticated appearance.

- Electrocoating: Providing uniform corrosion-resistant coating through an electrochemical process, ensuring enduring protection.

- Anodization: Creating a robust oxide layer, enhancing corrosion resistance and offering vibrant color selections.

- Powder Coating: Applying a resilient powder layer, delivering excellent protection and a range of color choices.

- Metal Plating: Utilizing diverse metals such as zinc, nickel, or chrome, enhancing appearance and corrosion resistance.

- Silk Screening: Applying intricate designs with accuracy, ensuring clear and detailed markings.

- Laser Etching: Utilizing laser technology for precise, permanent markings, elevating brand identity and traceability.

Our unwavering commitment to diverse, high-quality surface finishes ensures that our Custom Metal Assemblies not only meet but surpass industry standards, excelling in both functionality and visual allure.