Overview:

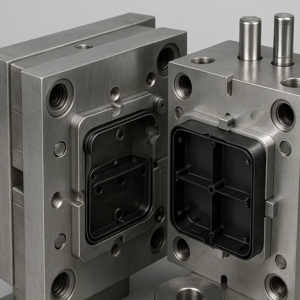

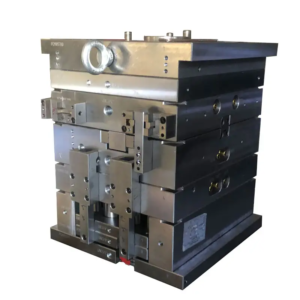

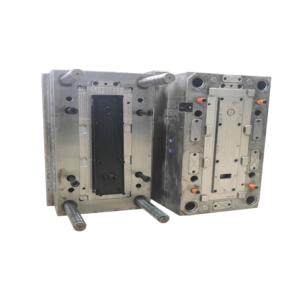

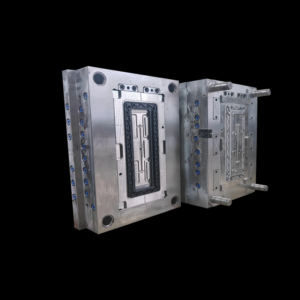

This precision mold is engineered for high-volume production of medical-grade syringe barrels, utilizing hardened tool steels (S136H/420SS) and multi-cavity hot runner systems to ensure ±0.01mm tolerances and cycle times under 15 seconds. Our ISO 13485-certified manufacturing integrates CNC machining, EDM, and conformal cooling channels for optimal thermal stability and longevity (500k+ cycles). Custom services include design-for-manufacturing (DFM) optimization, material selection (PP, COC), and validation testing (CMM, leak tests). As a one-stop solution provider, we deliver turnkey tooling with IATF 16949-compliant SPC controls, supporting OEMs in achieving FDA/CE-certified syringe production.

Characteristics:

| Specification | Details |

| Mold Material | P20 or H13 grade tool steel |

| Cavity Count | 8 cavities |

| Manufacturing Process | CNC machining, EDM (mirror & conventional), slowspeed wire cutting, polishing, heat treatment |

| Molding Technology | Precision medical-grade injection molding |

| Sample | Available upon request |

| OEM Service | Full custom tooling design, prototyping, and maintenance |

| Application | Production of medical syringe barrels for hospital use |

| Certification | ISO 13485, FDA 510(k) clearance |

| Dimensions | Custom per customer drawings |

| Lead Time | 30–45 days |

| Surface Finish | Texturing or mirror polish to client specification |

Benefits of Our Tooling:

-

- High‑Throughput Efficiency

Eight‑cavity design and optimized runner systems enable simultaneous molding of eight barrels per cycle, dramatically reducing cycle times and per‑unit costs for large‑scale hospital syringe production. - Precision Machining for Tight Tolerances

CNC‑machined steel cores and cavities, combined with mirror‑finish EDM, guarantee consistent wall thickness and dimensional accuracy, ensuring each barrel meets exact dosage and plunger‑fit specifications. - Advanced Cooling Channel Integration

Conformal cooling channels are precision‑drilled to deliver uniform thermal management, minimizing warpage and shrinkage while accelerating mold‑to‑mold cycle times. - Durable Tooling for Long‑Term Consistency

Constructed from hardened mold steels (P20 or H13) with surface treatments such as nitriding or chrome plating, the mold resists wear and corrosion—providing thousands of flawless cycles with minimal maintenance.

- High‑Throughput Efficiency

Surface Treatment Options:

-

- Mirror Polishing

Achieves an ultra‑smooth cavity finish to optimize material flow, improve part release, and minimize surface defects on medical syringe barrels. - Hard Chrome Plating

Deposits a wear‑resistant chrome layer that enhances corrosion protection and extends mold life under repeated medical‑grade sterilization cycles. - Electroless Nickel Plating

Provides a uniform, pore‑free nickel deposit for superior corrosion resistance and dimensional stability, even in complex mold geometries. - Titanium Nitride (TiN) Coating

Applies a thin, hard ceramic layer that increases surface hardness and lubricity, reducing friction and maintenance while ensuring precise, high‑volume production.

- Mirror Polishing

One-stop Service:

Our one-stop service delivers end-to-end solutions, including design-for-manufacturing (DFM) analysis, multi-cavity mold engineering (8-cavity hot runner systems), and ISO 13485-certified manufacturing with CNC/EDM processes (±0.005mm precision). We provide material selection guidance (USP Class VI PP/COC polymers), conformal cooling optimization (15–20% cycle time reduction), and validation protocols (IQ/OQ/PQ, CMM inspection, ASTM F838 leak testing). Custom services extend to rapid prototyping (10-day lead time), full PPAP documentation, and post-production support (mold maintenance, repair, and scalability adjustments). Backed by FDA 21 CFR Part 820 compliance and IATF 16949 SPC controls, we ensure turnkey tooling solutions for seamless, high-volume syringe production (50k+ units/day) with zero-defect alignment to hospital industry standards.

Factory Show:

Our state‑of‑the‑art manufacturing complex leverages precision CNC machining, mirror‑finish and conventional EDM, and slow‑speed wire‑cutting systems to deliver unmatched mold accuracy and durability. Our molding department operates 15 rubber compression presses alongside two cutting‑edge LSR injection machines, ensuring scalable production without compromising quality. To maintain exacting industry standards, we deploy advanced inspection tools—including 3D optical projectors, sealing integrity testers, Shore durometers, and elasticity gauges—under the oversight of our certified QA team. Accredited to ISO 9001 and IATF 16949, our facility upholds rigorous process controls and product integrity. Further boosting efficiency and consistency, we integrate automated AutoDryers, high‑speed doming stations, and precision die‑cutters, guaranteeing superior component precision at every stage.