Types of Metal Spring Clips

- Spring Retaining Clips:Used to retain or secure the position of components, such as electronic elements or light fixtures.

- Wire Spring Clips:Employed to securely fasten wires or cables, often found in electrical equipment and connectors.

- Sheet Metal Spring Clips:Crafted from thin sheet metal, these clips are used to fasten, connect, or hold components in assemblies.

- Injection Molded Spring Clips:Manufactured through injection molding, these clips are used to secure plastic components, such as panels or covers.

- Fastening Spring Clips:Designed for quick attachment and release of components, commonly used in automotive and household appliances.

- Pipe Spring Clips:Used to secure pipes and pipelines, ensuring they are held firmly and in a stable position.

- Slide-on Fastener Spring Clips:Applicable in scenarios requiring sliding fasteners or clamps, such as in furniture components.

Stainless metal clips are precision-engineered fastening components made from stainless steel. Widely employed for securing and joining materials, these clips find applications in various industries such as automotive, aerospace, and manufacturing.

Stainless metal clips are precision-engineered fastening components made from stainless steel. Widely employed for securing and joining materials, these clips find applications in various industries such as automotive, aerospace, and manufacturing.

Their corrosion-resistant properties make them ideal for use in diverse environments. Notable advantages include high durability, ease of installation, and the ability to withstand harsh conditions, ensuring reliable and long-lasting fastening solutions.

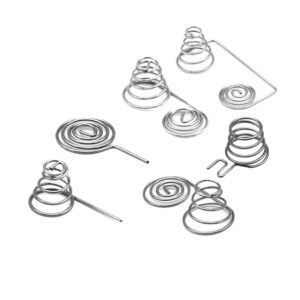

Metal spring clips, crafted through the advanced Fourslide process, feature diverse shapes and sizes, serving purposes like securing penlights, positioning distributor caps, or closing glove boxes. This precision manufacturing technique ensures versatility, enabling the production of customized clips for specific functions.

Why Choose Us

- From initial prototypes to large-scale production volumes, we cater to diverse manufacturing needs.

- Benefit from cost-effective in-house tooling, ensuring not only lowered expenses but also unparalleled quality control.

- Achieve intricate shapes and multiple bends, showcasing our expertise in handling complex metal forms.

- Validate functionality with our “soft tooled” prototypes, a precursor to flawless production execution.

- Harnessing high-speed production capabilities, we deliver up to 10,000 pieces per hour with precision akin to gauging standards.