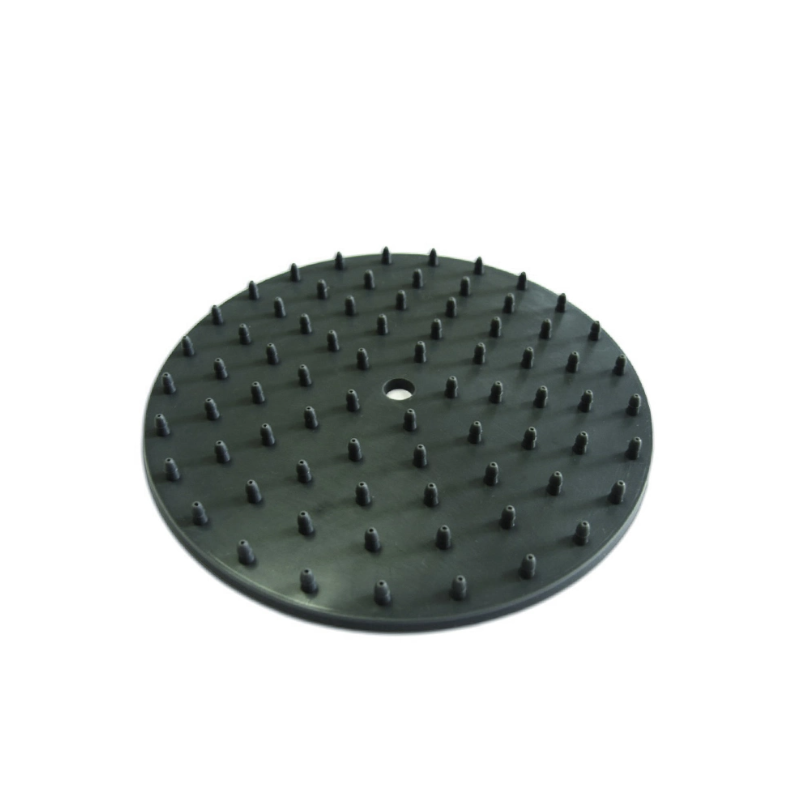

Custom Silicone Shower Nozzles are specially designed components used to enhance the functionality and aesthetics of shower systems. Crafted from high-quality silicone, these nozzles are manufactured using advanced silicone injection molding. This process ensures precise shaping, durability, and consistent performance. The silicone material provides a soft and gentle water flow, while the custom design options allow for tailored solutions to meet specific user preferences and bathroom styles. The result is a versatile and elegant shower nozzle that combines practical functionality with modern design.

Characteristics:

– Logo: Customizable

– Application: Suitable for bathroom use

– OEM/ODM: Available upon request

– Specification: Customizable to meet specific requirements

– Shaping Mode: Compression molding

– Certificate: ISO 9001, RoHS certified

– Production Capacity: 100,000 units

– Sample Time: 7-10 days

– Place of Origin: Xiamen, China

Benefits of Silicone Shower Nozzles:

– Gentle Water Flow: The premium silicone material delivers a soft, comfortable spray that is gentle on the skin.

– Adjustable Design: Features a flexible design that allows for easy adjustments to achieve the ideal water flow for a personalized shower experience.

– Low Maintenance: The smooth silicone surface resists build-up, simplifying cleaning and upkeep.

– Robust Durability: Constructed from high-grade silicone, these nozzles offer exceptional durability and reliable performance over time.

– Elegant Design Options: Available in a range of contemporary styles and colors, enhancing the aesthetic appeal of any bathroom.

Quality Assurance Procedures:

- Material Inspection: Ensure all silicone materials comply with safety and quality standards prior to the manufacturing process.

- Dimensional Accuracy Verification: Measure each nozzle to confirm it adheres to the specified design dimensions.

- Spray Pattern Evaluation: Assess the spray pattern for consistency and efficiency to guarantee optimal functionality.

- Durability Testing: Perform stress tests to evaluate the silicone’s durability and flexibility under various conditions.

- Build-Up Resistance Testing: Simulate usage to determine the nozzle’s resistance to mineral deposits and ease of cleaning.

- Color Fastness Testing: Evaluate color stability to ensure long-lasting vibrancy and resistance to fading over time and use.

- Final Quality Assessment: Conduct a thorough inspection of finished products, including visual checks for defects and compliance with specifications.

Customization Options for Silicone Shower Nozzles:

– Shape and Size: Tailored designs to suit specific shower setups and individual preferences.

– Color Choices: Available in a diverse range of colors, including custom Pantone shades, to match any bathroom decor.

– Surface Finishes: Options for various surface textures, such as matte, glossy, or patterned, to enhance visual appeal.

– Logo and Branding: Custom logos or branding can be applied through methods such as screen printing or embossing.

– Flow Rate Adjustments: Customizable flow rates to meet specific performance needs.

– Packaging Solutions: Customized packaging options to align with branding requirements or retail specifications.