Hello, everyone, as we all know,in today’s fast-paced world, the demand for innovative and high-quality products continues to grow. As a result, companies are constantly looking for ways to streamline their product development processes in order to bring new and improved products to market quickly. One method that has attracted a lot of attention in recent years is rapid prototyping, particularly in the case of silicone rubber keyboards. In this blog, we’ll take a closer look at what rapid prototyping with silicone rubber keyboards is, its benefits, and its overall impact on the product development and manufacturing process.

Silicone rubber keyboards are an integral part of a variety of electronic devices, including remote controls, medical equipment, industrial machinery, and consumer electronics. These keyboards are known for their durability, tactile feedback, and resistance to environmental factors such as moisture, dust, and chemicals. Given its importance in a variety of applications, the need for rapid prototyping in silicone rubber keyboard development cannot be overstated.

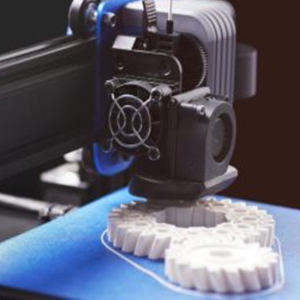

Rapid prototyping of silicone keyboards involves using advanced manufacturing technologies such as 3D printing and silicone molding to create physical prototypes quickly and cost-effectively. This process allows designers and engineers to validate their designs, test functionality and make necessary iterations before entering full production. The advantages of rapid prototyping of silicone rubber keyboards are manifold and have a profound impact on the entire product development cycle.

One of the main benefits of using silicone keyboards for rapid prototyping is the ability to speed up product development time. Traditional prototyping methods often require long lead times and higher costs, which can significantly delay the entire product development process. Rapid prototyping allows designers and engineers to quickly turn their digital designs into physical prototypes, allowing them to iterate and refine products faster. This not only reduces time to market, but also provides companies with a competitive advantage in meeting consumer demand for innovative products

Additionally, rapid prototyping allows for greater design flexibility. Silicone rubber keyboards come in a variety of shapes, sizes and configurations to meet different product requirements. Rapid prototyping allows designers to easily try out different design iterations, haptic patterns, and button layouts to optimize the user experience. This flexibility allows the company to fine-tune its product designs based on user feedback and market trends, ultimately creating a more ergonomic and user-friendly silicone keyboard.

In addition to speed and flexibility, rapid prototyping also plays a vital role in reducing risks associated with product development. By producing physical prototypes early in the design process, potential design flaws and functionality issues can be identified and resolved before investing in expensive tooling and production. This proactive approach not only minimizes the possibility of costly design changes late in the development cycle, but also improves the overall quality and reliability of the silicone keyboard.

Another significant advantage of using silicone rubber keyboards for rapid prototyping is the cost-effectiveness it provides. Traditional prototyping methods often involve significant upfront processing and manufacturing costs, especially when producing low-volume prototypes. Rapid prototyping, on the other hand, significantly reduces the initial investment required to create a prototype, making it a more economical option for companies (especially startups and small businesses) that want to validate their product designs without incurring excessive expenses.

Additionally, rapid prototyping facilitates seamless collaboration among cross-functional teams involved in the product development process. With ready-made physical prototypes, designers, engineers and stakeholders can engage in real-world evaluation and testing, promoting effective communication and decision-making. This collaborative approach not only speeds up the design iteration process but also ensures that all parties are aligned on the product specifications needed to realize the silicone keyboard.

In addition to the above advantages, rapid prototyping of silicone rubber keyboards also aligns with sustainability initiatives. By producing accurate and optimized prototypes, companies can minimize the material waste and energy consumption associated with traditional prototyping methods. Additionally, the ability to quickly iterate on designs reduces the potential for overproduction and unnecessary resource utilization, thereby promoting more sustainable approaches to product development and manufacturing.

![]()

In summary, the importance of rapid prototyping with silicone rubber keyboards cannot be overstated. From accelerating product development time and increasing design flexibility to reducing risk and cost, rapid prototyping serves as a catalyst for innovation and efficiency in the creation of silicone keyboards. As technology continues to advance, the adoption of rapid prototyping will undoubtedly pl ay a key role in shaping the future of product development, allowing companies to bring high-quality silicone keyboards to market with unprecedented speed and precision.

We hope this blog provides valuable insight into the importance of rapid prototyping of silicone rubber keyboards. As always, we thank our readers and look forward to sharing more informative content in the future.Okay,guys,see you next time!