Hi, friends, today I bring you about the use of CNC in the medical industry, I hope this article will give you some help.In the ever-evolving field of medical technology, the introduction of computer numerical control (CNC) machining has revolutionized the manufacturing process of medical devices and components. This advanced manufacturing technology has had a major impact on the medical industry, enabling the precise and efficient production of complex parts critical to a variety of medical applications. In this blog, we’ll delve into the intricacies, processes, and practices of medical CNC machining to shed light on its importance and the advancements it brings to the medical field.

Medical CNC machining technology

CNC machining involves using computer controls and machine tools to remove material from a workpiece to create a custom-designed part or product. In medical manufacturing, CNC machining plays a key role in producing complex components such as surgical instruments, orthopedic implants, dentures, and medical device housings with unparalleled precision and accuracy.

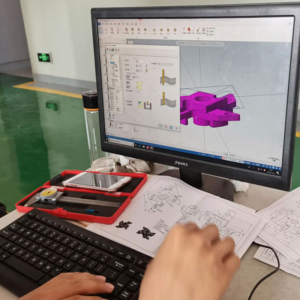

The process begins by using computer-aided design (CAD) software to create digital 3D models of the required medical components. This digital model is the blueprint that the CNC machine tool follows. The next step is to convert the CAD model into a set of instructions (called G-code) that dictate the specific movements and operations that the CNC machine will perform when making the part.

After the G-code is generated, the CNC machine operator loads the corresponding cutting tools and raw materials into the machine tool. The machine then performs a precise series of movements based on programmed instructions to cut, drill and shape the material. The result is a carefully crafted medical component that meets the exact specifications outlined in the initial CAD model.

After the G-code is generated, the CNC machine operator loads the corresponding cutting tools and raw materials into the machine tool. The machine then performs a precise series of movements based on programmed instructions to cut, drill and shape the material. The result is a carefully crafted medical component that meets the exact specifications outlined in the initial CAD model.

Medical CNC machining practice

Medical CNC machining practices cover a variety of specialized techniques and considerations tailored to the unique requirements of the medical industry. One of the main considerations for medical CNC machining is material selection. Medical devices and components often require biocompatible materials that are safe for long-term contact with the human body. Titanium, stainless steel, and medical-grade plastics are commonly used materials in medical CNC machining due to their biocompatibility and mechanical properties.

In addition, the tolerances and surface finish of medical parts produced through CNC machining are also critical. The complexity of medical devices requires extremely tight tolerances to ensure correct functionality and compatibility with other components.CNC machining enables micron-level precision, allowing the production of parts with minimal dimensional changes. Additionally, the surface finish of medical components is critical as it affects biocompatibility, sterilization, and overall performance. CNC machining techniques such as milling, turning and grinding can achieve the precise surface finishes required for medical applications.

Quality control and regulatory compliance are integral aspects of medical CNC machining practices. Strict quality assurance measures are implemented, including in-process inspections and post-production testing, to verify the dimensional accuracy and material integrity of medical components. Additionally, regulatory standards such as ISO 13485 and FDA regulations must be adhered to to ensure the safety and effectiveness of medical devices manufactured through CNC machining.

Quality control and regulatory compliance are integral aspects of medical CNC machining practices. Strict quality assurance measures are implemented, including in-process inspections and post-production testing, to verify the dimensional accuracy and material integrity of medical components. Additionally, regulatory standards such as ISO 13485 and FDA regulations must be adhered to to ensure the safety and effectiveness of medical devices manufactured through CNC machining.

The significance of medical CNC machining

The introduction of medical CNC machining has brought about a paradigm shift in the production of medical devices and components. Its importance lies in its ability to meet the stringent requirements of the medical industry, where accuracy, reliability and safety cannot be ignored. Here are some key aspects that highlight the importance of medical CNC machining:

- Customization and Complexity: Medical CNC machining is capable of producing highly customized and complex parts that are tailored to the specific needs of patients and healthcare providers. From patient-specific implants to complex surgical instruments, CNC machining can create complex geometries and complex features that are impossible with traditional manufacturing methods.

- Time and cost efficiency: Despite the complexity of medical components, CNC machining offers significant efficiencies in production time and cost. The automation and repeatability of CNC machining processes shortens lead times and reduces production costs, making it a viable solution for prototyping and large-scale manufacturing in the medical field.

- Innovation and Progress: The precision and versatility of CNC machining paves the way for innovation and progress in medical technology. From the miniaturization of medical devices to the development of novel implant designs, CNC machining enables medical device manufacturers to push the boundaries of what is possible, driving progress and innovation in the field.

- Reliability and consistency: The determinism of CNC machining ensures consistent quality and reliability in the production of medical components. Requiring minimal human intervention and being able to replicate precise geometries, CNC machining provides unparalleled consistency, which is critical to ensuring the safety and effectiveness of medical devices.

The future of medical CNC machining:

The future of medical CNC machining:

As technology continues to advance, the future of medical CNC machining is expected to be further enhanced and innovative. Integrating advanced materials such as biodegradable polymers and composites into medical CNC machining provides opportunities to develop next-generation medical devices with enhanced biocompatibility and performance.

Additionally, the convergence of CNC machining and additive manufacturing technologies (commonly known as 3D printing) is expected to revolutionize the production of medical components. The ability to manufacture complex, patient-specific implants and prostheses with a high degree of customization and precision is a compelling prospect that could reshape the landscape of personalized medicine.

All in all, the introduction of medical CNC machining has redefined the manufacturing landscape of the medical industry, providing unparalleled precision, customization and efficiency for the production of critical medical components. The processes and practices of medical CNC machining embody a commitment to excellence, safety and innovation, driving the advancement of medical technology and ultimately improving patient care and outcomes. Looking ahead, continued advances in medical CNC machining have the potential to shape the next generation of medical devices and push the industry toward new frontiers of possibility.Friends, please leave a message to tell me if there is any need to correct this content. We will be happy to contact you to discuss.