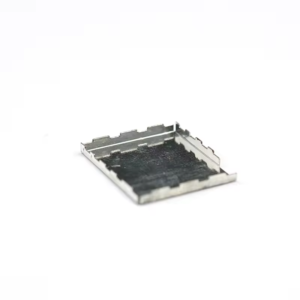

Characteristics:

| Feature | Description |

| Place of Origin | Xiamen, China |

| Brand | Custom OEM |

| Model | Custom OEM |

| Product Name | Circuit Board Shielding |

| Material | High-Quality Steel |

| Surface Finish | Durable Powder Coating |

| Color Options | Customizable |

| Size Options | Customizable |

| Applications | Suitable for Ceiling, Wall, and Floor |

| Samples | Available Upon Request |

| Minimum Order Quantity (MOQ) | 500 Pieces |

| Processing Method | Precision Stamping |

| Mold Requirements | Necessary for Production |

Packaging Details:

– Inner Packaging: Clear bags

– Outer Packaging: Cartons, followed by palletizing

– Custom Packaging: Available upon request

Shipping Information:

– Port: Xiamen

– Selling Units: Single item

– Single Package Size: 10 x 10 x 2 cm

– Single Gross Weight: 0.300 kg

Ordering Process:

- Submission of Drawings and Samples

– Customers provide detailed drawings and physical samples.

- Material and Mold Specification

– Determine the required materials and mold specifications.

- Price Negotiation

– Discuss and finalize pricing based on requirements.

- Prototype Development

– Create and review initial prototypes for validation.

- Sample Confirmation

– Customers provide feedback on samples and approve for production.

- Commencement of Mass Production

– Begin large-scale manufacturing following sample approval.

- Packaging and Logistics

– Pack products according to specifications and arrange shipping.

- Receipt Confirmation

– Customers confirm receipt of the final products.

Our Advantages:

-

Low MOQ

– We accept small minimum order quantities.

-

Assembly Services

– Comprehensive assembly services are available.

-

Expert Sales Support

– Our dedicated sales team provides excellent pre-sales and after-sales support.

-

Design Optimization

– Experienced engineers offer design and production optimizations to save costs for customer projects.

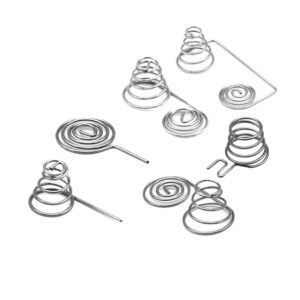

Common Surface Treatments:

-

Zinc Plating

– Adds corrosion resistance with a protective zinc layer.

-

Nickel Plating

– Increases durability and corrosion resistance through a nickel coating.

-

Chrome Plating

– Provides a shiny, corrosion-resistant finish via electroplated chromium.

-

Powder Coating

– Applies a dry powder, cured under heat, for a durable, decorative finish.