Overview:

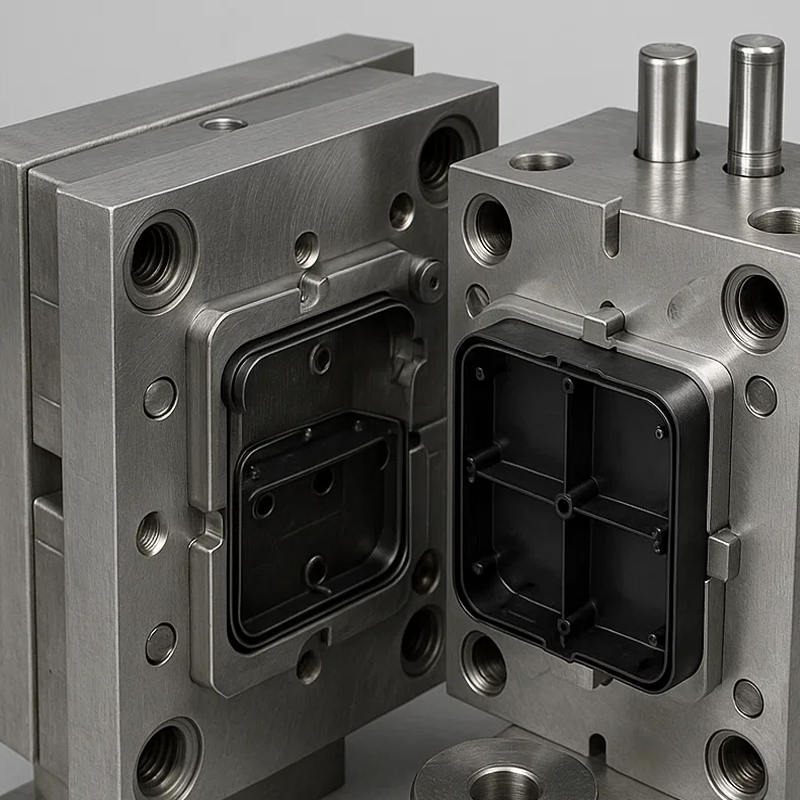

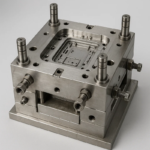

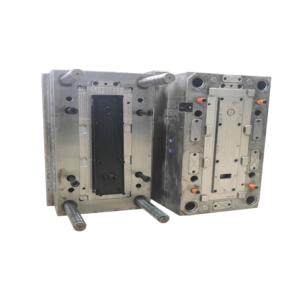

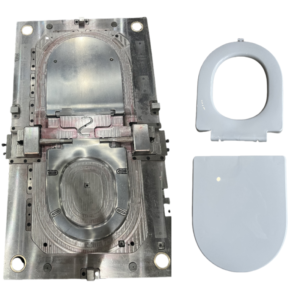

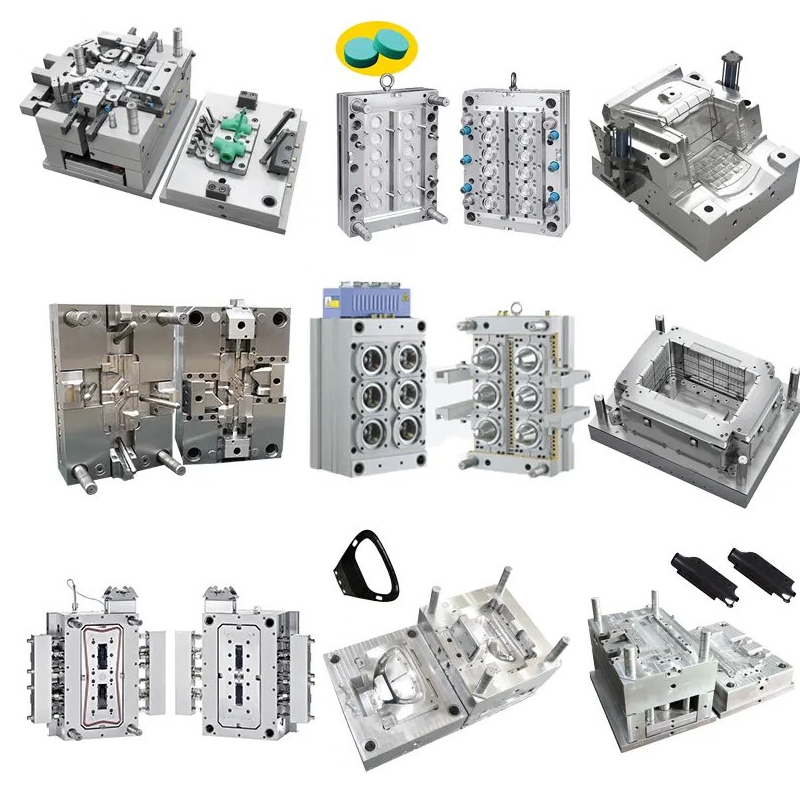

The OEM Premium Plastic Injection Molding Tooling Mold for Electronic Housings Application is a high-precision solution engineered to produce durable, high-performance plastic housings for electronic components. Crafted from top-tier materials like steel or aluminum, these molds employ cutting-edge manufacturing technologies, including CNC machining, EDM (Electrical Discharge Machining), and advanced injection molding techniques. This ensures exceptional accuracy, repeatability, and operational efficiency.Our factory offers comprehensive one-stop services, including custom tooling solutions, material selection, and surface treatment options, all tailored to meet your specific requirements. We also provide assembly and testing to guarantee the highest product quality and functionality. Fully compliant with IATF 16949 and ISO 9001 standards, our molds deliver superior durability and precision, ensuring optimal performance for all electronic housing applications.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Steel, Aluminum, High-Grade Plastics |

| Runner System | Hot/Cold Runner |

| Mould Design Software | UG, PROE, SOLIDWORKS, CAD |

| Sample | Available |

| Certification | ISO 9001, IATF 16949 |

| Packaging | Custom |

| MOQ | Based on Requirements |

| Lead Time | 25–30 days |

Surface Treatment Options:

- Nickel Plating: Provides corrosion resistance and extends mold life in challenging environments.

- Hard Anodizing: Enhances surface hardness, ideal for high-precision electronic housings.

- Chromium Plating: Ensures superior wear resistance and longevity.

- Polishing: Refines mold surfaces to reduce friction and improve component quality.

Quality Assurance:

Our quality assurance for OEM Premium Plastic Injection Molding Tooling Mold for Electronic Housings Application adheres to strict international standards. Certified to ISO 9001 and IATF 16949, we ensure comprehensive compliance with top-tier quality management systems. Our inspection process includes first-article evaluations, in-process audits, and final product assessments. We utilize coordinate measuring machines (CMM) for precision, hardness testers to verify material properties, and surface roughness analyzers to ensure mold surface integrity. Additionally, automated vision systems and material testing guarantee consistency and durability in every mold produced.

Why Choose Us?

- Large Parts & Low Volumes: We specialize in handling both large parts and low-volume production runs without compromising quality.

- Low Tooling Costs: Our optimized tooling processes minimize your upfront costs while maintaining precision.

- Design Freedom: We offer flexible design options, enabling you to meet specific electronic housing requirements.

- Complex Geometry: Our advanced injection molding technology supports the production of complex, intricate mold geometries.

- Comprehensive Quality Assurance: Our state-of-the-art inspection tools ensure that every mold meets strict quality standards, providing consistent performance and reliability.

Factory Show:

Our advanced manufacturing facility integrates precision technologies like CNC machining, Mirror EDM, conventional EDM, and Slow-Speed Wire Cutting (WC) to ensure the highest levels of accuracy in mold fabrication. We operate 15 rubber compression molding presses and 2 LSR injection molding machines, enabling us to scale production efficiently while maintaining optimal performance. Our quality control team uses cutting-edge tools such as 3D projectors, sealing testers, durometers, and elasticity gauges to ensure precision and consistency. Fully certified under ISO 9001 and IATF 16949, we guarantee high-performance manufacturing with automated systems like AutoDryers, high-speed doming machines, and precision die-cutting technology to improve productivity and product quality at every stage of production.