Overview:

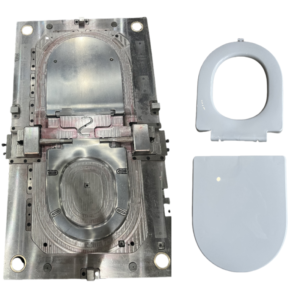

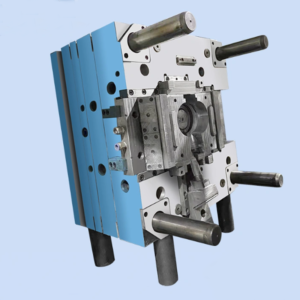

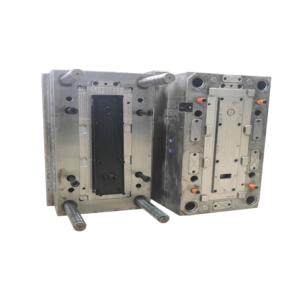

Our factory excel in manufacturing OEM Food Grade Silicone Ketchup Valves Mold Tooling designed for efficient, hygienic, and high-performance bottle dispensing applications. The tooling is crafted from premium materials such as tool steel, stainless steel, or aluminum alloys, and utilizes advanced manufacturing processes like CNC machining, EDM, and heat treatment for maximum precision and durability. Our customized molds ensure seamless integration with bottle dispensing systems, providing optimal flow control for sauces and condiments. Our one-stop service includes design support, prototyping, mold testing, and mass production, delivering cost-effective, high-quality solutions tailored to meet your specific requirements.

![]()

Basic Information:

| Specification | Details |

|---|---|

| Material Options | Tool Steel (P20, H13), Stainless Steel (304/316), Aluminum Alloy (6061-T6) |

| Sample Lead Time | 7–15 days |

| Production Lead Time | 3–5 weeks |

| Process | CNC Machining, EDM, Heat Treatment, Precision Grinding |

| Surface Finish | Polished or Textured (Ra ≤ 0.8μm) |

| Customization | Full OEM Support (Design to Production), One-Stop Service |

| Certifications | ISO 9001, RoHS Compliance |

Benefits of Our Mold:

- Enhanced Surface Durability via Plasma Nitriding

Plasma-nitrided surfaces enhance mold hardness to 1,100–1,300 HV, reducing wear and ensuring over 500,000 cycles in high-pressure vulcanization, ideal for high-demand silicone food packaging. - Precision Thermal Management

FEA-optimized conformal cooling channels ensure uniform mold-face temperatures with a ±2°C tolerance, preventing curing inconsistencies and flash formation in intricate valve designs. - Tight-Tolerance Tool Fabrication

CNC and EDM technologies deliver ±0.005mm dimensional accuracy, crucial for ensuring precise flow control in ketchup dispensing valves, meeting ISO 3601-3 compliance and strict leakage standards. - Corrosion-Resistant Material Integrity

H13 tool steel, pre-hardened to 38–42 HRC and coated with CrN PVD, resists degradation from ketchup acids and sulfurized rubber compounds, extending tool life and reducing downtime for maintenance.

Surface Treatment Options for Our Tooling:

- Plasma Nitriding

Enhances mold hardness and wear resistance, providing a longer tool life for high-cycle molding operations. - PVD Coating (Physical Vapor Deposition)

Adds an additional layer of corrosion and wear resistance, ideal for food-grade applications subject to acidic or abrasive conditions. - Hard Chrome Plating

Offers excellent corrosion resistance and superior surface finish, ensuring easy ejection of silicone parts and preventing sticking. - Ceramic Coating

Provides exceptional heat resistance, making it ideal for molds exposed to high temperatures during the compression molding process.

Quality Assurance:

Our rigorous quality assurance processes ensure that each mold meets the highest standards for food-grade applications. We use advanced testing methods, including spectrometry for material validation, Coordinate Measuring Machines (CMM) for dimensional accuracy, and Rockwell/Clemex microhardness testers to assess plasma nitriding surface hardness. We also conduct thermal cycling tests and corrosion resistance simulations to validate the mold’s performance under demanding conditions. Our facility is ISO 9001 and IATF 16949 certified, ensuring consistent quality control throughout every stage of production.

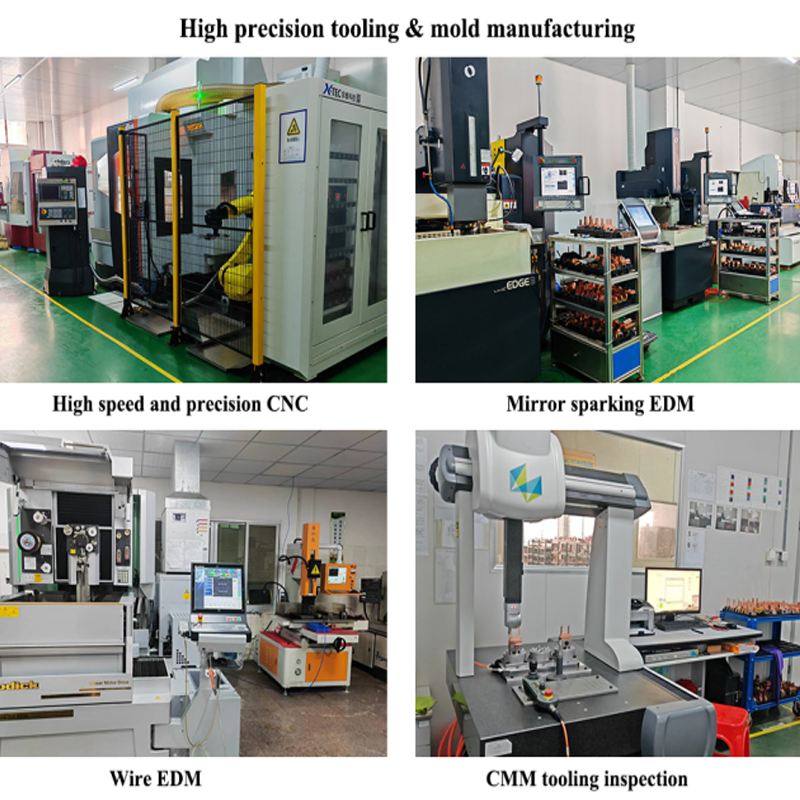

Factory Show:

Our factory is equipped with state-of-the-art technologies, including CNC machining, Mirror EDM, conventional EDM, and slow-speed wire-cutting systems, to ensure exceptional precision and repeatability in mold fabrication. With 15 rubber compression molding machines and 2 LSR injection molding units, we are capable of handling high-volume, time-sensitive production demands. Our advanced quality control equipment, including 3D projectors, sealing integrity testers, durometers, and elasticity gauges, guarantees that every mold is inspected for safety, performance, and consistency.

Fully compliant with ISO 9001 and IATF 16949 certifications, we combine cutting-edge technology with rigorous quality standards to deliver molds that meet the most stringent industry requirements for food-grade silicone dispensing systems. Our use of automated systems, including AutoDryers, high-speed doming machines, and precision die-cutting equipment, ensures maximum efficiency, productivity, and product integrity throughout the entire production process.