Overview:

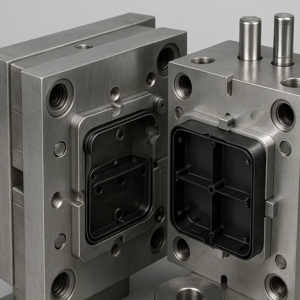

The Custom High Precision Steel Shower Nozzle Mold Tooling for Bathroom Parts is a highly engineered solution designed to manufacture durable and precise shower nozzles used in bathroom fittings. Constructed from high-quality materials like premium steel, this mold leverages advanced EDM (Electrical Discharge Machining) and CNC machining technologies to ensure exceptional accuracy and superior performance. Tailored for the bathroom parts industry, this mold offers precision-crafted tooling to meet the high standards of quality and durability required for bathroom fixtures and accessories.

As a trusted manufacturer, we provide end-to-end services, including custom tooling designs, rapid prototyping, and efficient, high-volume production. Our tooling solutions are compliant with ISO 9001 and IATF 16949 certifications, ensuring that each mold meets the highest industry standards for quality, consistency, and reliability.

Key Specifications:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Product Material | High-Precision Steel |

| Runner System | Hot/Cold Runner |

| Mold Design Software | UG, PROE, SOLIDWORKS, CAD, etc. |

| Sample | Available |

| Certification | ISO 9001, IATF 16949 |

| Packaging | Custom Packaging Solutions |

| MOQ | According to customer requirements |

| Lead Time | 25-30 days |

| Surface Treatment Options | Nickel Plating, Hard Anodizing, Chromium Plating, Polishing |

Surface Treatment Process:

-

- Nickel Plating: Offers exceptional corrosion resistance, increasing mold lifespan in wet and demanding environments.

- Hard Anodizing: Strengthens the mold’s surface, making it highly resistant to wear and tear.

- Chromium Plating: Ensures long-lasting protection against corrosion and wear, maintaining mold performance over time.

- Polishing: Reduces friction during molding, improving the quality of molded components and ensuring smoother operation.

Benefits of Our Tooling:

- Exceptional Precision: Our molds are manufactured using advanced EDM and CNC machining technologies, ensuring high precision and consistent performance across all production runs. Every detail of the shower nozzle mold is crafted with extreme accuracy to meet the high standards required for bathroom fixtures.

- Durability and Corrosion Resistance: The high-quality steel and surface treatments like nickel plating and hard anodizing ensure that the molds remain durable, resistant to corrosion, and capable of withstanding harsh production environments, particularly in wet conditions typical of bathroom parts.

- Efficient Production: With hot/cold runner systems and advanced CNC capabilities, our tooling allows for high-volume production with minimal waste and maximum efficiency. This reduces the cost of each molded part while maintaining consistent quality and precision.

- Customization and Flexibility: Our custom-designed molds provide flexibility in molding complex shapes and ensuring the perfect fit for your specific shower nozzle and bathroom parts. We work closely with you to meet exact specifications, providing a tailored solution for your business needs.

Quality Assurance:

We adhere to rigorous quality management practices that are in compliance with ISO 9001 and IATF 16949 certifications. Each shower nozzle mold undergoes a multi-step inspection process to ensure it meets the highest industry standards:

- First-Article Evaluation: We assess the first produced sample for dimensional accuracy and mold functionality.

- In-Process Audits: Continuous monitoring of the manufacturing process to maintain quality standards.

- Final Product Assessment: Complete inspection of the mold and final products to verify durability, dimensional accuracy, and surface quality.

We use advanced inspection tools such as Coordinate Measuring Machines (CMM), hardness testers, surface roughness analyzers, and automated vision systems to ensure the molds’ precise dimensions and superior material integrity.

Why Choose Us?

- Precision Engineering: With our advanced EDM and CNC machining capabilities, we deliver molds with exceptional precision that are perfectly suited for the high standards of bathroom parts and accessories.

- Long-Term Durability: Our surface treatments like nickel plating and hard anodizing ensure that our molds last longer and perform reliably in demanding environments.

- Custom Solutions: We offer custom mold designs, tailored to your specific product needs, and flexible options for high-volume production, ensuring that the molds fit seamlessly into your production process.

- Certified Quality: We maintain ISO 9001 and IATF 16949 certifications, ensuring that our molds meet the highest quality standards in the industry.

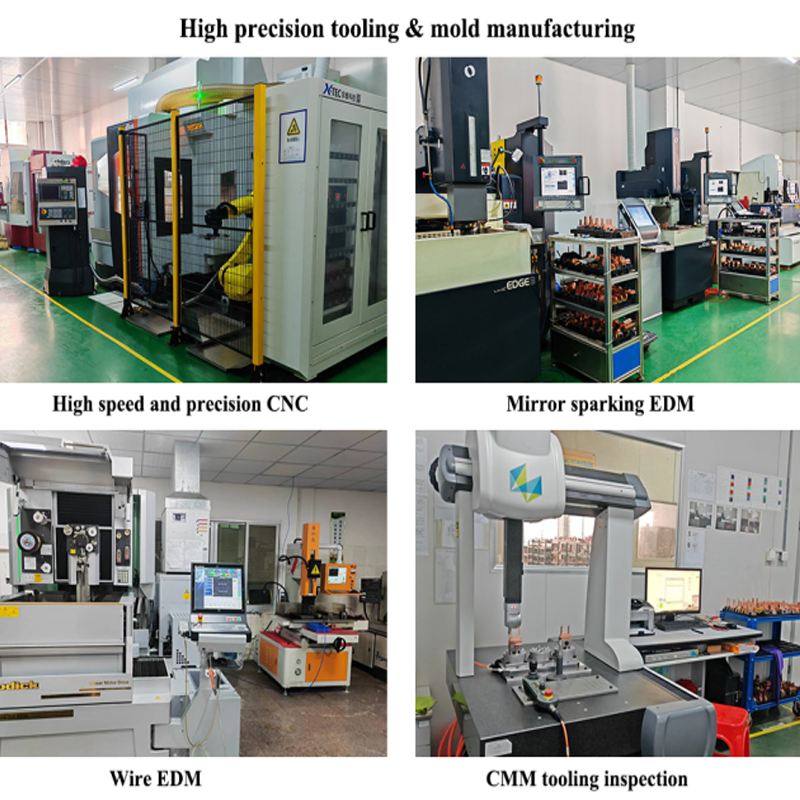

Factory Capabilities:

Our state-of-the-art manufacturing facility is equipped with the latest technologies, including CNC machining, Mirror EDM, conventional EDM, and Slow-Speed Wire Cutting (WC), allowing us to achieve exceptional precision in mold fabrication. With 15 rubber compression molding presses and 2 LSR injection molding machines, we ensure consistent performance and fast production.

Our advanced inspection tools, such as 3D projectors, sealing testers, durometers, and elasticity gauges, are used to guarantee the highest standards of mold quality, and our certified quality control team ensures that every component meets your exact specifications.

Additionally, we utilize automated systems like AutoDryers, high-speed doming machines, and precision die-cutting technology to optimize production, enhance productivity, and maintain consistent quality throughout the manufacturing process.