Overview:

We specialize in the manufacture of plastic injection molds and parts for plastic electronics housings and enclosures, such as plastic electricity meter box mold, plastic water meter box mold, plastic loud speaker mold, plastic switch box mold, plastic camera housing mold, plastic phone case mold, plastic power bank mold, plastic door bell mold, plastic wire harness mold, plastic terminal block mold, plastic earphone plug mold, etc. We do both tooling and parts mass production. Welcome to have your own molds and parts custom made.

Details:

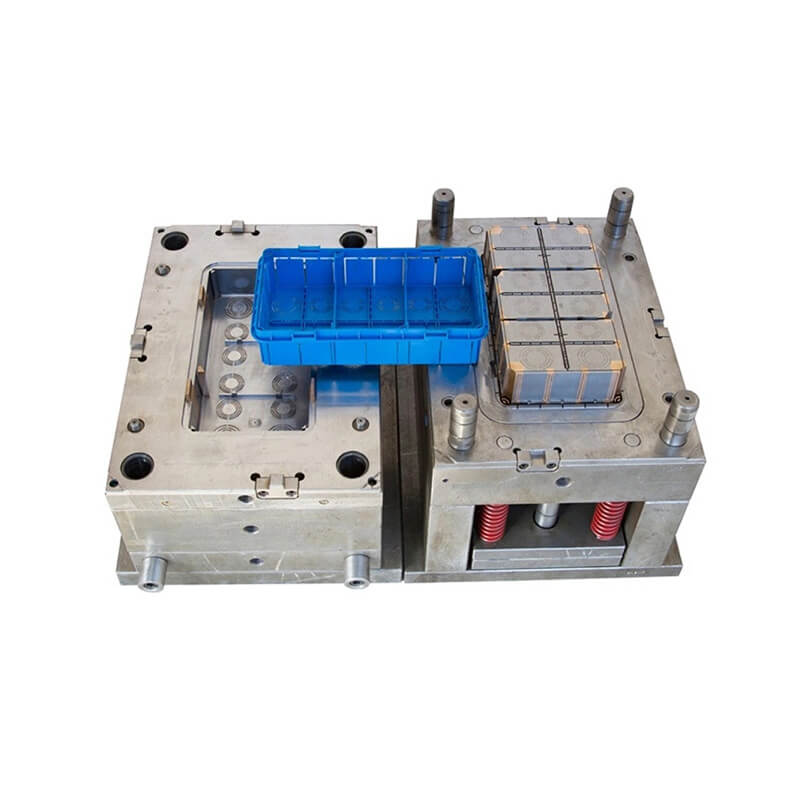

| Item Name | Custom Injection Plastic Electricity Meter Box Mould / Mold |

| Manufacturing Method | Plastic Injection Molding |

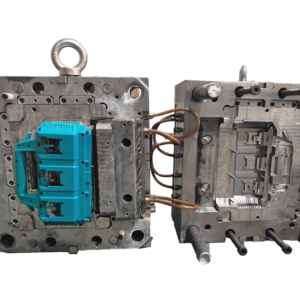

| Runner System | Cold Runner or Hot Runner (Valve Gate available) |

| Parts Material | Both hard and soft plastics, such as PP, ABS, HDPE, LDPE, PET, PVC, PA6, PA66, Nylon, PMMA, Acrylic, PVC, PU, TPU, PC, PS, HIPS, PC/ABS, POM, EVA, TPR, TPE, Delrin, PBT, etc. |

| Parts Color | 1, Transparent / Clear

2, Any Color, Opaque (match as per pantone color number) |

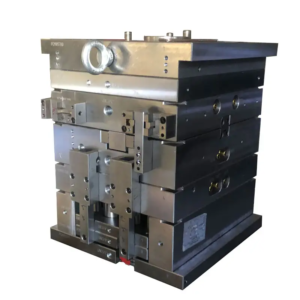

| Mould Material | NAK80, S136, 2316, 2738, H13, 5CrNiMo, 718H, P20, 40Cr, 60#, 45# etc |

| Mould Cavity | Single or Multi, as per your requirements |

| Gate Type | Sprue gate, Pin-point gate, Submarine gate, etc |

| Design Software / Program | UG, PROE, Solidworks, etc. |

| Surface Treatment | Polished (Glossy or common), Matte, Textured |

| Mould Life | 10,000-1,000,000 shots |

| Mold Building Lead Time | 15-60 days (average 30 days for medium size molds) |

| Payment Terms | T/T, Western Union, Paypal |

| Mould Packaging | Fumigation-free Plywood Wooden Case |

| Transportation | By Sea or by Air, as per your requirements |

| Export Countries | Worldwide (US, UK, Canada, Romania, Sweden, Italy, Russia, India, Iran, etc.) |

| Capabilities | 1, Mold Building (common molds, hot runner molds, metal-to-plastic over molding / insert molding)

2, Parts Production 3, Logo Printing (Pad printing, Silk Screen Printing, Ultrasonic Welding, Painting, Plating, etc.) 4, Assembling (as per your detailed requirements) 5, Packing and Shipping |

We should quote and proceed as per 3D files or samples. 3D files format can be STP/STEP or IGS/IGES or X_T.

Our customer are from all over the world, such as The United States, UK, Canada, Sweden, Romania, Italy, Russia, India, Iran, etc. We always accept small orders to support our customers for better marketing. Our new customers can talk to some of our regular clients when they are ready to start.