Hello there, It’s still us, Thesun Industry,keypad lovers! Today, we’re going to take a deep dive into the world of keyboard materials to help you make an informed decision between choosing a silicone or plastic keyboard. We know, it’s not the most exciting topic, but hey, we promise to make it as fun as possible. So grab your favorite drink, sit back, and let’s get into the ins and outs of your keyboard’s materials.

So let’s explore them!

Silicone rubber keypads and plastic keypads serve as input interfaces across diverse sectors like medical, industrial, automotive, and consumer electronics. Each option presents distinct advantages and drawbacks, pivotal in aligning with your application’s requirements.

Explore the comparison between these keypads, encompassing aesthetics, molding techniques, tactile feedback, durability, adaptability, and cost considerations.

Aesthetics:

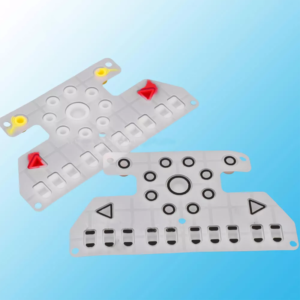

Silicone keypads offer a tactile, rubbery feel that’s comfortable to touch, with the flexibility to be molded into various shapes and sizes, including 3D and contoured designs. Custom silicone keypads can feature personalized layouts achieved through backlighting and laser etching, ensuring durable markings for intricate designs, ideal for control panels and user interfaces in diverse applications. Renowned for durability, silicone is often preferred for industrial settings.

![]()

On the other hand, plastic keypads provide a more rigid and tactile response, suitable for precise input. They excel in consumer electronics, offering customization options for brand-specific colors and surface textures. Plastic keypads can incorporate in-mold decorating and backlit symbols through laser etching, making them ideal for applications requiring illuminated key labels.

Molding Process:

Silicone Keypad Molding Process:

In compression silicone rubber molding, silicone undergoes mixing with curing agents and additives before being injected into a steel or silicone mold via a molding machine. Within the mold, subjected to heat and pressure, the silicone cures to assume the mold’s shape. The design, key alignment, and tactile features of the silicone keypad are defined by the cavities within the mold and the positioning of tactile elements.

Plastic Keypad Molding Process:

For plastic injection molding, the process begins with the design of the keypad and the selection of the suitable resin. Through injection molding, plastic keypads are formed, involving the injection of molten plastic material into a mold cavity under high pressure.

![]()

Tactile Feedback Mechanisms:

Silicone Keypads:

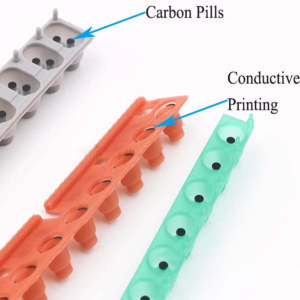

Silicone keypads utilize silicone rubber webbing to provide tactile feedback. Upon pressing a key, the silicone webbing collapses, exerting pressure on a conductive pill within the keypad’s circuitry. This action completes the circuit, delivering the tactile sensation users experience when pressing a key.

Plastic Keypads:

In contrast, plastic keypads employ a dome switch mechanism to offer tactile feedback. Each key features a tactile dome—a small, flexible plastic piece with a central protrusion. When a key is pressed, the dome compresses, producing both a tactile sensation and an audible click.

Durability and Environmental Resistance:

Silicone Keypads:

Silicone keypads are renowned for their ruggedness and resilience. They excel in harsh environments, enduring extreme temperatures, chemicals, and UV radiation with ease. This makes them the preferred choice for applications exposed to moisture, dust, and chemicals, commonly found in industries like automotive and industrial equipment. Additionally, silicone’s non-conductive nature mitigates electrical interference risks, enhancing safety.

Plastic Keypads:

The durability of plastic keypads varies depending on the specific material used. While hard plastics such as polycarbonate and ABS offer decent impact resistance, they may not match silicone rubber’s resilience to extreme conditions. Plastic keypads are susceptible to wear and tear over time, especially in demanding environments.

Adaptability:

Silicone Rubber Keypads:

Renowned for their remarkable flexibility, silicone rubber keypads excel in accommodating intricate shapes and designs. This adaptability is particularly advantageous in applications requiring ergonomic and customized key layouts. Moreover, silicone keypads offer a quieter keypress, making them ideal for noise-sensitive environments like medical devices or industrial equipment.

Plastic Keypads:

While plastic keypads boast a wide array of color options, their design flexibility is comparatively limited when contrasted with silicone rubber keypads.

Cost Considerations:

Silicone Rubber Keypads:

While silicone rubber keypads may incur higher initial costs due to quality materials and complex molding processes, their durability and prolonged lifespan contribute to long-term cost savings. With reduced maintenance needs and less frequent replacements, silicone keypads offer an economically viable solution over time.

Plastic Keypads:

Plastic keypads typically offer a more cost-effective manufacturing process compared to silicone alternatives. With readily available materials and streamlined molding techniques, production costs are minimized. However, it’s important to account for potential replacement and maintenance expenses, especially in demanding environments where plastic keypads may exhibit reduced durability.

Choosing Between Silicone Rubber and Plastic Keypads:

When it comes to selecting between silicone rubber and plastic keypads, various factors come into play, such as user experience, environmental conditions, tactile feedback preferences, and budget considerations. Silicone rubber keypads stand out for their durability and reliability, particularly in challenging environments. On the other hand, plastic keypads offer cost-effective solutions and a wider range of aesthetic options.

For expert assistance in sourcing plastic or customized silicone rubber keypads, look no further than Nelson Miller Group. With expertise in diverse keypad applications, including Human Machine Interfaces, industrial controls, computing peripherals, remotes, laboratory equipment, and medical devices, we’re here to address your needs. Contact us today to explore our comprehensive solutions!

So, which one should you choose? Well, it ultimately comes down to your specific needs and preferences. If you work in an environment where spills and dust are a constant concern, a silicone rubber keyboard may be the better option for you. Its durability and resistance to environmental factors make it a practical choice for such settings. On the other hand, if you prioritize affordability and a wide range of design options, a plastic keyboard may be more suitable for your needs. Consider factors such as where and how you’ll be using the keyboard, as well as your personal typing preferences, to make an informed decision.

![]()

We hope this blog has shed some light on the differences between silicone rubber and plastic keyboards, helping you make a more informed decision when it comes to choosing the right keyboard for your needs. If you have any questions or need further assistance, feel free to reach out to us. And don’t forget to stay tuned to our website for more insightful content on all things tech and gadgets. Happy typing!