Overview:

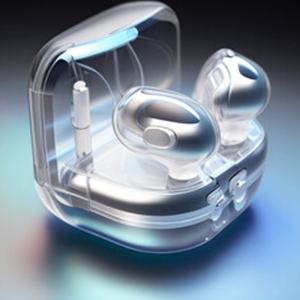

Designed for medical applications, the Durable Medical PC Materials Connector used in conjunction with silicone masks exemplifies precision through injection molding. The utilization of high-quality, medical-grade materials ensures the connector meets stringent industry requirements for hygiene, durability, and biocompatibility. This versatile component plays a pivotal role in a range of medical devices, contributing to the reliability and longevity of critical healthcare equipment.

Basic Information:

| Transportation | Sea,Express,Train,Air |

| Sample | Available |

| Origin | Xiamen,China |

| Trade Terms | FOB,CIF,CFR,EXW |

| OEM | Available |

| CERTIFICATE | ISO |

The Advantages of Our Connector:

-

Superior Durability:

The connector is constructed from robust medical-grade polycarbonate (PC) materials, ensuring exceptional durability and longevity in medical environments.

-

Customization Flexibility:

Offers versatile customization options, allowing for tailored adaptations to accommodate specific mask designs and medical requirements.

-

Secure and Reliable Connection:

Engineered to provide a secure and reliable connection, ensuring seamless integration with silicone masks for enhanced patient safety and comfort.

-

Biocompatible Composition:

Prioritizes biocompatibility with medical-grade materials, minimizing the risk of adverse reactions and ensuring the connector’s compatibility with various skin types.

-

Precision Engineering:

Manufactured with precision engineering to guarantee accurate dimensions, promoting a snug fit and optimal functionality when used with silicone masks.

The Production Process of Connector:

-

Material Selection:

– Start with the meticulous selection of high-quality medical-grade PC (Polycarbonate) materials to ensure biocompatibility and compliance with medical device standards.

-

Design and Engineering:

– Employ a team of biomedical engineers to design and engineer the connector, adhering to precise specifications and ergonomic considerations for seamless integration with silicone masks.

-

Tooling and Molding:

– Develop specialized molds and tooling for the injection molding process, enabling the production of connectors with intricate geometries and dimensional accuracy.

-

Injection Molding of PC Materials:

– Utilize advanced injection molding techniques to introduce medical-grade PC materials into the molds under controlled temperature and pressure conditions, ensuring the formation of durable and defect-free connectors.

-

Quality Control and Testing:

– Implement rigorous quality control measures, including visual inspection and dimensional checks, to verify the integrity of each connector. Conduct material testing to confirm compliance with medical standards.

-

Surface Treatment:

– Apply medical-grade surface treatments, such as antimicrobial coatings or biocompatible finishes, to enhance the durability and safety of the connector for medical applications.

-

Assembly of Silicone Mask Interface:

– Integrate the connector seamlessly with the silicone mask interface, employing precision assembly techniques to guarantee a secure and airtight connection.

-

Sterilization:

– Subject the assembled connectors to validated sterilization processes, such as gamma irradiation or ethylene oxide sterilization, to ensure the elimination of microbial contaminants and maintain product sterility.

-

Packaging:

– Employ cleanroom facilities for the packaging process, utilizing sterile packaging materials and procedures to safeguard the connectors from contamination during storage and transportation.

-

Documentation and Regulatory Compliance:

– Compile comprehensive documentation, including manufacturing records, quality control reports, and compliance certificates, to meet regulatory requirements and facilitate traceability throughout the product life cycle.