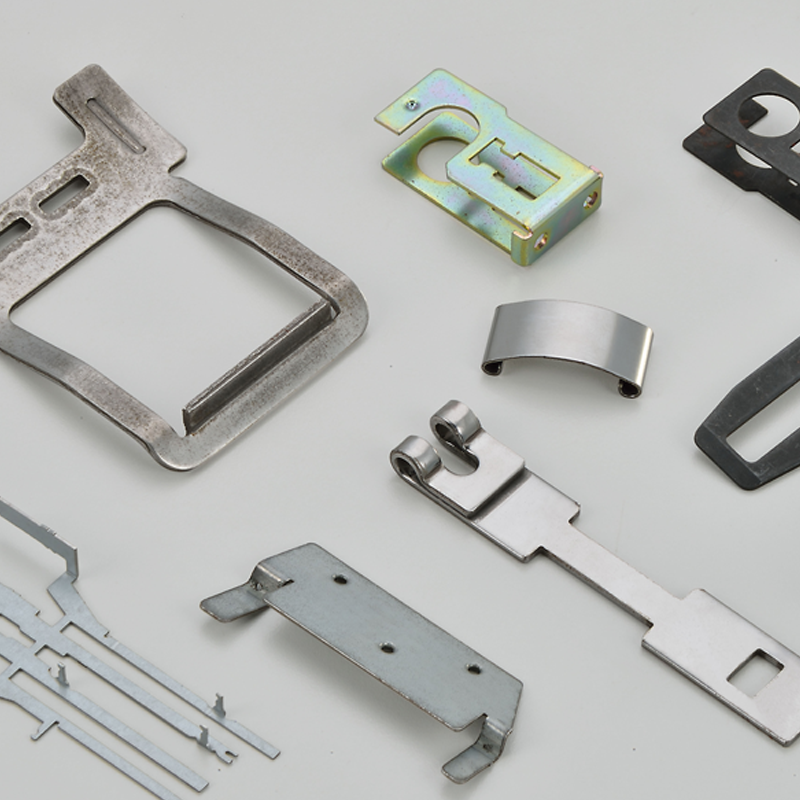

Are you evaluating finishing options for high-precision components and wondering whether precision grinding is the right step in your process chain? At Thesun Industry, our factory handles grinding as part of a full one-stop service — from stamping and heat treat through finishing and assembly — and we work closely with customers and suppliers to deliver repeatable, ready-to-assemble parts. This guide explains the fundamentals of grinding, its history, key parameters, common processes, pros and cons, costs, environmental considerations, and how CNC grinding is applied today.

What is the Grinding Process and Its Basic Principles?

Grinding (abrasive machining) removes material by the controlled action of abrasive grains in a wheel or belt. Each abrasive grain acts like a tiny cutting tool. By selecting grit, bond, wheel speed and feed, engineers control material removal rate, dimensional accuracy, and surface finish (Ra). Grinding excels at finishing hardened surfaces, tight-tolerance geometries, and achieving fine surface integrity.

How Has Grinding Technology Evolved?

- Ancient origins: Hand-finishing and abrasive stones were used for millennia to refine metal and tools.

- Industrial Revolution: Mechanized wheels and early machine tools enabled repeatable finishing for mass production.

- Early 20th century: Purpose-built surface and cylindrical grinders emerged for bearings and precision tooling.

- Mid–late 20th century: New abrasives (CBN, diamond) and coolant systems improved productivity and allowed grinding of hard alloys.

- Modern era: CNC-controlled multi-axis grinding, in-process metrology and adaptive controls deliver micron-level tolerances in automated production.

Technical Specifications in Grinding

Key parameters you must monitor and control:

- Grinding wheel speed (rpm): Affects cutting action and heat generation.

- Workpiece speed: Important for cylindrical and centerless operations.

- Feed rate: Traversing speed impacts surface waviness and cycle time.

- Depth of cut: Governs stock removal per pass and wheel load.

- G-ratio: Volume of material removed vs. wheel wear — indicates wheel life.

- Surface finish (Ra): Target dependent on function (bearing surfaces vs. cosmetic).

- Coolant application: Controls temperature, flushes swarf and extends wheel life.

Types of Grinding Processes and Applications

- Surface grinding: Flatness and finish for plates, dies, and housings.

- Cylindrical grinding: Shafts, pins and journals with tight concentricity.

- Internal grinding: Precision bores and ID features.

- Centerless grinding: High-volume shafts without centers.

- Creep-feed grinding: Heavy single-pass removal in hard materials.

Common Techniques

- Traverse vs. plunge grinding: Different feed motions for forms or OD/ID features.

- Wet vs. dry grinding: Wet (with coolant) is standard for heat control.

- Spark-out: Finishing pass without feed to stabilize geometry.

Materials That Can Be Ground

Steel, stainless, tool steels, hardened alloys, carbide (with diamond/CBN), ceramics and glass — selection of wheel type (A/Oxide, SiC, CBN, diamond) depends on work material.

Advantages and Limitations

Advantages: unmatched accuracy, excellent surface finish, ability to grind hardened parts.

Limitations: lower material removal rates than milling, potential thermal damage if uncontrolled, requirement for wheel dressing and secondary operations.

Cost and Environmental Impact

Cost drivers include machine amortization, wheel and dressing costs, coolant systems and labor. Environmental impact centers on coolant disposal and particulate control — many modern factories invest in filtration, coolant recycling and capture systems to minimize waste and comply with regulations.

Precision CNC Grinding in Modern Manufacturing

CNC grinding integrates CAD/CAM, multi-axis motion and in-process probing to produce complex geometries with consistent tolerances. For contract manufacturers and OEMs, combining stamping or forging with in-house grinding reduces supply-chain friction. Thesun Industry’s custom service packages include process qualification, SPC, and turnkey supply of finished components to assembly-ready specifications.

Conclusion

Precision grinding is a cornerstone technology when you need micron-level accuracy, superior surface finish, and dimensionally stable parts — especially for bearings, tooling, medical implants and aerospace components. If your project requires finished metal stamping parts or hardened components produced with full traceability, our factory at Thesun Industry provides engineering support, prototype-to-volume grinding, and a seamless one-stop service. Want us to review your drawing for grind feasibility or provide a quote including finish targets and lifecycle costs? Contact our team — we’ll evaluate tolerances, propose grinding strategies, and match the right suppliers and processes to meet your manufacturing goals.