Overview:

Custom Plastic and Metal Overmolding & Aluminum Deep Drawing of Progressive Stamping Electronic Cigarette Cover Parts are precision-engineered components designed to meet the demanding requirements of modern electronic cigarette devices. Combining advanced overmolding techniques with high-precision aluminum deep drawing and progressive stamping processes, these parts deliver exceptional structural integrity, aesthetic appeal, and functional performance. Manufactured from high-grade materials such as engineering-grade plastics and lightweight aluminum alloys, each component is engineered to provide durability, ergonomic comfort, and reliable protection for sensitive internal electronics. As a specialized manufacturer with deep industry expertise, we offer comprehensive OEM solutions tailored to your design and performance specifications. Our integrated manufacturing approach, supported by stringent quality control, ensures consistent output that enhances device longevity, user experience, and brand value.

Characteristics:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Dimension | As per drawing or customer sample |

| Sample Availability | Yes |

| Certification | ISO 9001:2015, IATF 16949:2016, RoHS |

| OEM Services | Yes |

| Inspection | 100% in-house factory inspection |

| MOQ | Based on customer requirements |

| Tolerance | ±0.02mm or customized |

| After-Sale Service | Provided |

Key Processes:

-

Plastic and Metal Overmolding:

This process involves molding thermoplastic materials (such as PPSU, PC, or ABS) directly onto metal substrates—typically aluminum or stainless steel—to form a seamless, integrated component. The result is enhanced grip, improved aesthetic appeal, vibration dampening, and superior waterproof and dustproof performance, ideal for electronic cigarette enclosures. -

Aluminum Deep Drawing:

Using high-precision deep drawing dies, aluminum sheets are formed into seamless, complex hollow shapes with consistent wall thickness. This technique is ideal for producing lightweight yet robust covers and structural housings that resist deformation and corrosion. -

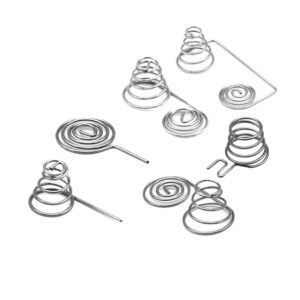

Progressive Stamping:

Multi-stage stamping dies mounted on high-speed presses enable efficient, high-volume production of intricate metal components with tight tolerances. This process is used for forming vents, contacts, and mounting features in a single automated sequence.

Surface Treatment Options:

-

Two-Shot Injection Molding: Combines two different colors or material types in a single molding cycle for aesthetic differentiation and functional zoning.

-

Texture Painting & Soft-Touch Coating: Enhances grip and provides a premium tactile experience while masking minor surface imperfections.

-

NCVM (Non-Conductive Vacuum Metallization): Adds a high-end metallic appearance without interfering with wireless signal transmission.

-

Anodizing: Improves aluminum surface hardness and corrosion resistance while allowing for a wide range of color options.

-

Laser Etching & Logo Marking: Ensures permanent branding, serial numbers, or decorative patterns with high precision.

Quality Assurance:

Our quality assurance system for Custom Plastic and Metal Overmolding & Aluminum Deep Drawing Electronic Cigarette Cover Parts is built around a rigorous, multi-stage inspection protocol. Certified under ISO 9001:2015 and IATF 16949:2016, we employ state-of-the-art metrology equipment including 3D optical scanners, CMM (Coordinate Measuring Machines), and material composition analyzers to validate dimensional accuracy, material properties, and surface quality. All parts undergo 100% in-house inspection for critical attributes such as wall thickness, bonding integrity between plastic and metal, and cosmetic finish. Our dedicated quality team ensures every component meets performance specifications for drop resistance, sealing effectiveness, and aesthetic standards required by leading electronic cigarette brands.

Factory Show:

Our manufacturing facility is equipped with advanced machinery tailored to high-volume production of precision overmolded and stamped electronic cigarette components. The plant features 20–350 ton injection molding machines with multi-material molding capabilities, high-speed progressive stamping presses (25–300 tons), deep drawing hydraulic presses, and automated robotic assembly units. We also operate dedicated cleanrooms for finishing processes such as NCVM, laser engraving, and precision assembly. With integrated ultrasonic welding, leak testing stations, and full traceability throughout production, we deliver components that meet the highest standards of precision, consistency, and reliability. All operations are certified to ISO 9001 and IATF 16949, reflecting our unwavering commitment to quality, innovation, and customer satisfaction.